High-viscosity inkjet ink

- Top Page

- Search by Application

- High-viscosity inkjet ink

What is high-viscosity inkjet ink?

Differences between high viscosity inkjet printing and conventional inkjet printing.

What is inkjet ink?

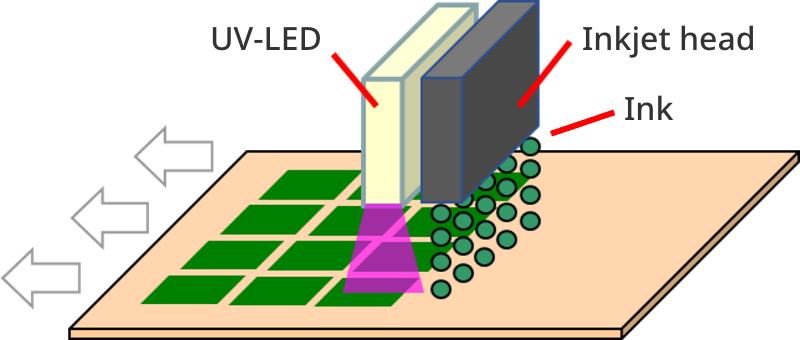

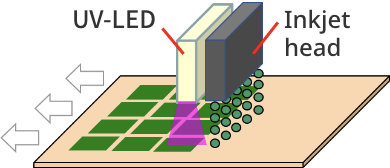

"Inkjet" refers to a method of printing by jetting tiny droplets of photocurable ink, approximately 20μm in size, from the nozzles of an inkjet head.

High-viscosity inkjet ink is a product that can jet within previously difficult viscosity ranges.

Three features of inkjet printing

- On-demand printing : Printable in any shape, such as circles and straight lines, on the desired places. No need for processes such as etching, making it possible to reduce processing processes.

- Non-contact printing : Printable on uneven surfaces of the substrates.

- No need for screen masks : Printable with reduced materials.

Two advantages of high-viscosity inkjet

High-viscosity inkjet materials offer two advantages over conventional inkjet.

High functionality

Compatible with many materials, allowing for high heat resistance and high strength.

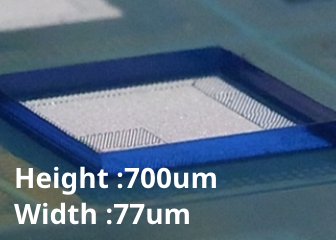

Shape flexibility (high resolution)

The high-viscosity properties of the material prevent spreading and enable high-resolution printing.

Advantages of the Sekisui Chemical's high-viscosity inkjet

Optimizing the printing process is the key challenge.

While high-viscosity inkjet has many advantages, it requires the preparation of devices and materials and the optimization of the printing processes in order to use it.

Competitive advantage

Sekisui Chemical collaborates with device manufacturers, enabling one-stop solutions including the printing processes.

- Inkjet technology requires

materials (ink), devices, and printing processes. -

- Even with these things individually in place, successful printing is not possible.

-

- Our one-stop solution development enables you to achieve ink application optimization.

-

Features of the high-viscosity inkjet system

High functionality materials ✕ Shape flexibility

Proprietary high-functionality materials, designed uniquely from adhesives to barrier rid forming materials

-

High heat resistance

High heat resistance

-

High chemical resistance

High chemical resistance

-

High adhesion

High adhesion

-

Low outgassing

Low outgassing

-

High light-blocking properties

High light-blocking properties

Freely controllable ink application shape

-

Flat shape

Flat shape

-

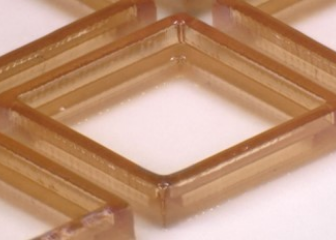

Barrier rid forming materials (DAMs)

Barrier rid forming materials (DAMs)

-

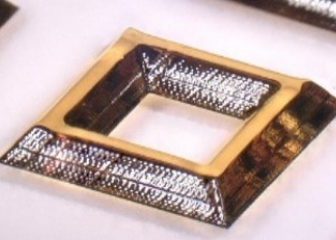

Step-like shape

Step-like shape

-

Inclined shape

Inclined shape

-

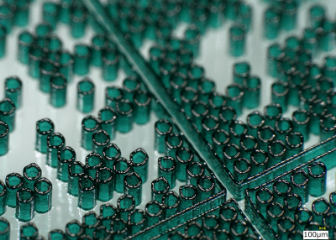

Cylindrical shape

Cylindrical shape

Two advantages of high-viscosity inkjet

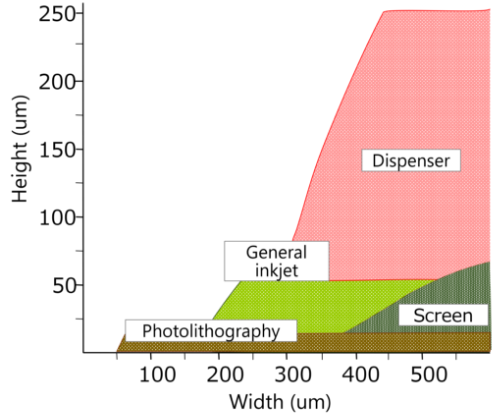

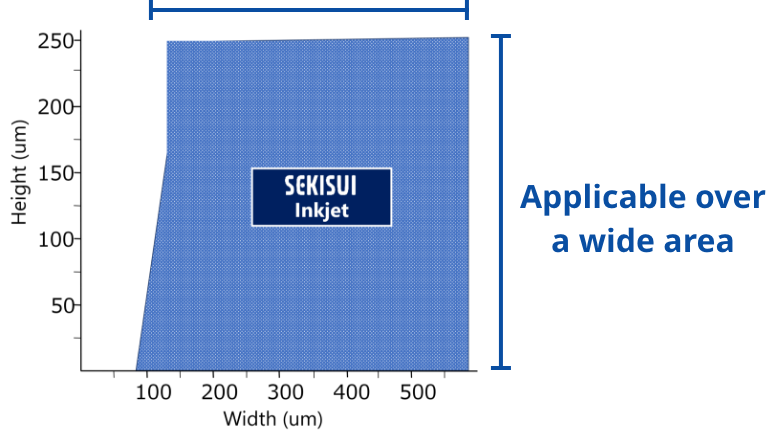

Sekisui Chemical's inkjet, due to its high viscosity, allows for high-definition ink pattern application with minimal spreading after ink hits the surface.

It can be applied in a thin, yet high and upright pattern, which is difficult to achieve with other printing methods, such as dispenser usage while offering the advantages of "wide-range printing" and "reduced production processes," resulting in high performance.

Figure1Comparison of printing methods

| Printing method | Resolution | Height | Total cost | Process time | Features |

|---|---|---|---|---|---|

| Sekisui Inkjet | ○ | ○ | ○ | ○ |

|

| General inkjet | × | × | ○ | ○ |

|

| Screen | × | × | ○ | ○ |

|

| Dispenser | × | ○ | ○ | × |

|

| Photolithography | ○ | × | × | × |

|

Figure2Comparison of printing range and height by method

Other methods + Conventional inkjet method

Conventional inkjet printing method

Process comparison

Process comparison between photolithography (*) and inkjet printing methods

Photolithography method

- Mixture

- Screen

printing - Prebake

- Exposure

- Development

- Postbake

hardening

What is "photolithography" ?

This is a technique that involves applying photoresist onto a substrate, followed by exposure and development processes in a patterned manner, to generate circuit patterns and the like.

Inkjet Printing

-

Inkjet printing + UV curing

-

Heat curing

Contributing to process improvement, elimination of developing solution, high productivity due to solvent-free operation, and reduced environmental impact

Sekisui Chemical's high-viscosity inkjet contributes to achieving high resolution through miniaturization and reducing total costs through process shortening.

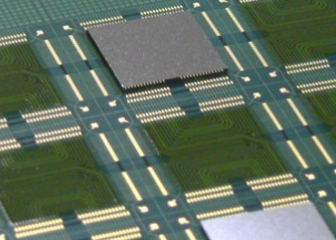

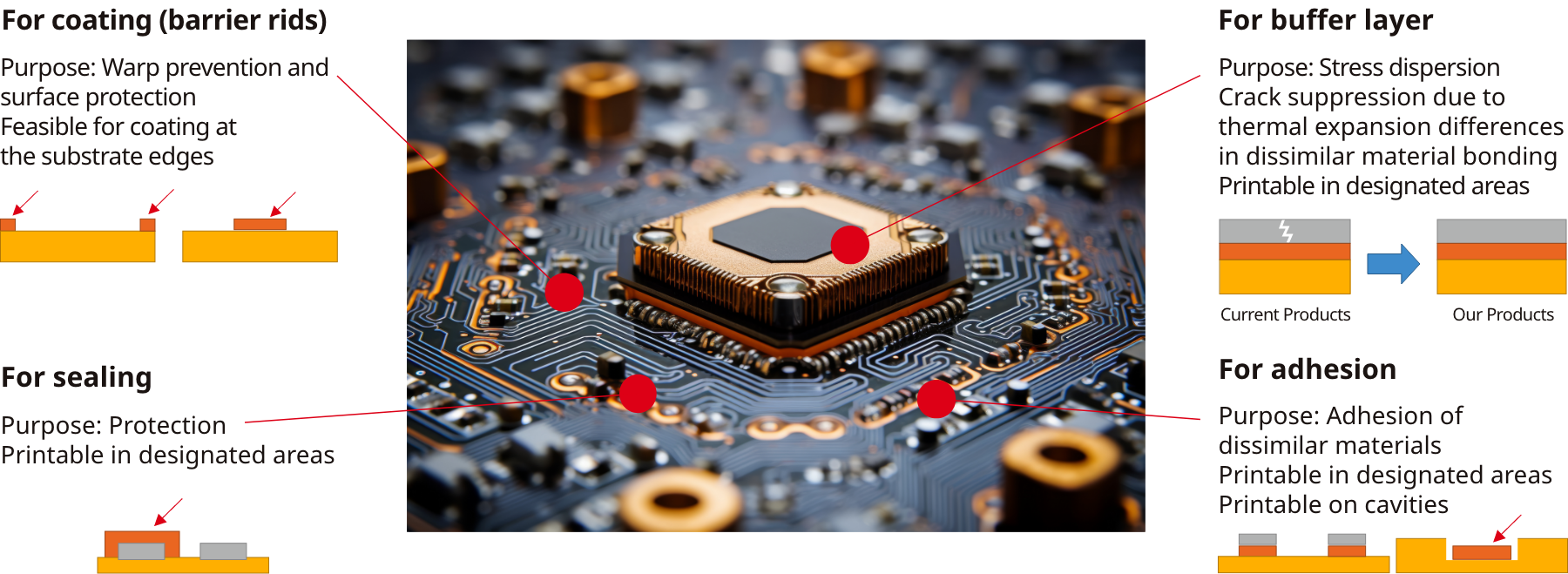

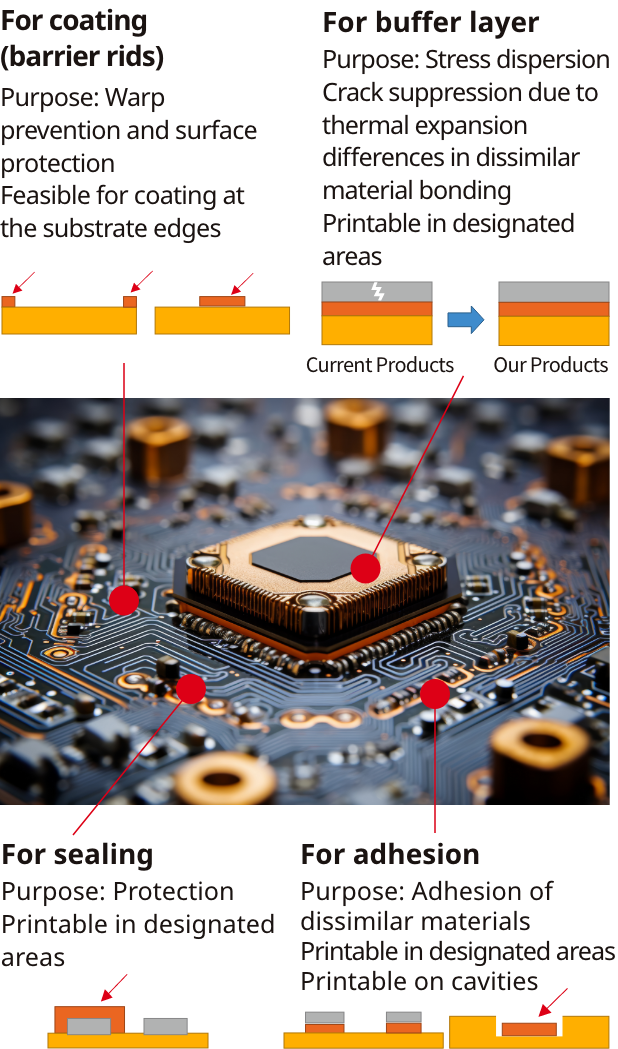

Application examples

Our high-viscosity inkjet can be used for a wide variety of applications including mobile phones, displays, and substrate packaging.

For forming printing patterns and advancing functionalities of exterior peripheries

For miniaturizing packaging and other objects

Other applications

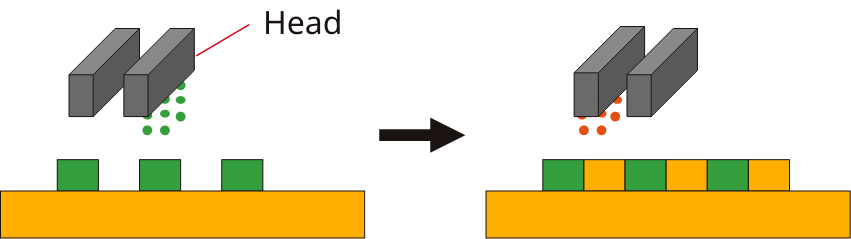

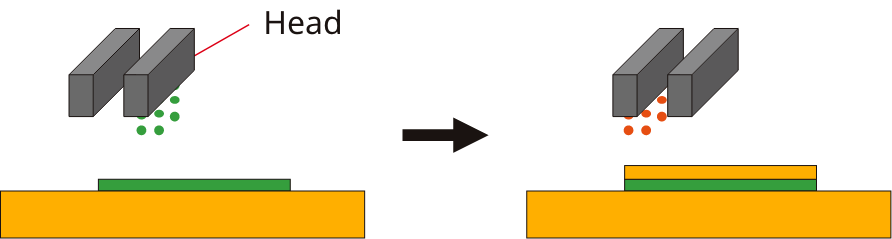

Several inks from multiple-head devices can be dispensed in one process.

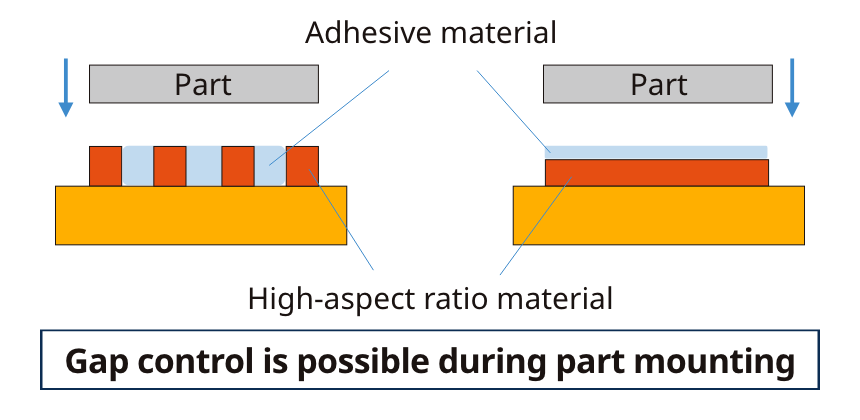

Usage example 1 Gap control adhesive

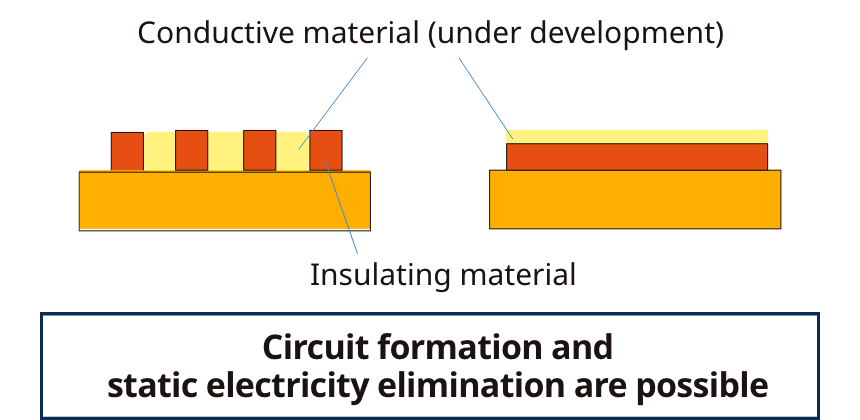

Usage example 2 Insulating + Conductive properties

Please let us know your various needs and requests.

Sales and technical support team for this product will be provided.

- Those interested in fine application with dispensers

- Those interested in improving productivity with 3D printers

- Those interested in high-performance functionality using inkjet

Specialized printing

Those seeking a wide range of sizes and shapes, including cylindrical, plate-like, inclined, and step-like shapes.

contribute to solving customers' problems.