Metal-plated Micropearl™

- Top Page

- Microsphere (Micropearl™)

- Metal-plated Micropearl™

Metal-plated particles with uniform particle size distribution

Metal-plated Micropearl™ can be used for conduction between electronic devices and substrate, thermal conduction, gap formation, and others.

It can also serve as a high-performance light-weight filler with uniform particle size distribution and flexibility.

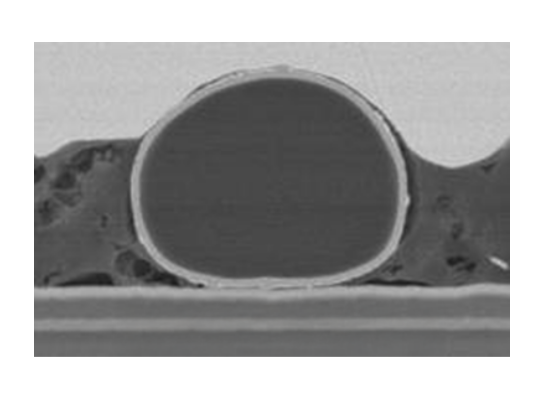

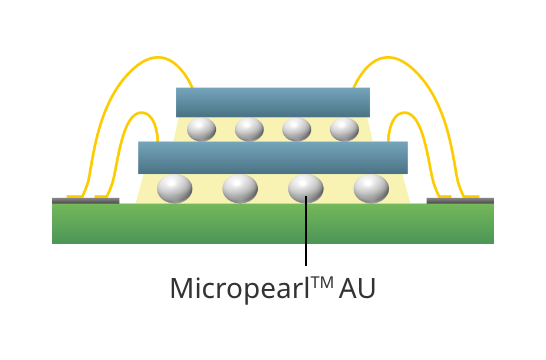

Constituent material of ACF (Anisotropic Conductive Film)

Challenge

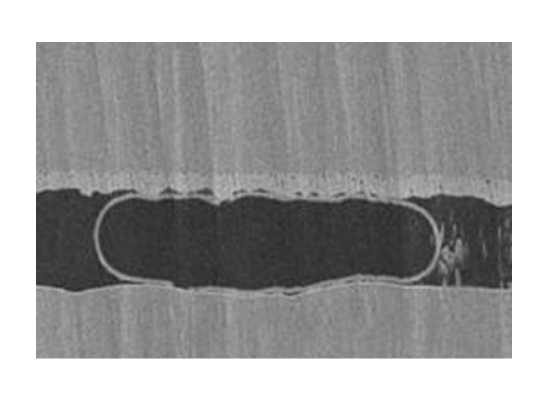

In display devices in general, including smartphones and TVs, the display definition is becoming higher and higher. In recent years, the mounting part is being downsized and display pitch is being narrowed in order that the whole surface of display body displays images as seen in such displays as bezel-less, foldable, and flexible displays.

What makes it possible to achieve the above is mounting by means of ACF, and conductive particles used in them are also required to have a high quality.

SEKISUI's Solution

- With a wide range of finely-classified particle sizes and various hardnesses, we make optimum proposals.

- Integrated manufacturing beginning with resin particles, which serve as the base material, allows us to achieve advanced customization and quality warranty.

- We also have various proprietary technologies in addition to basic material particles and plating, and will contribute to the improvement of conduction reliability and anisotropic conductivity.

Our products are maintaining the industry’s No. 1* share as conductive filler for ACF.

- According to our own research

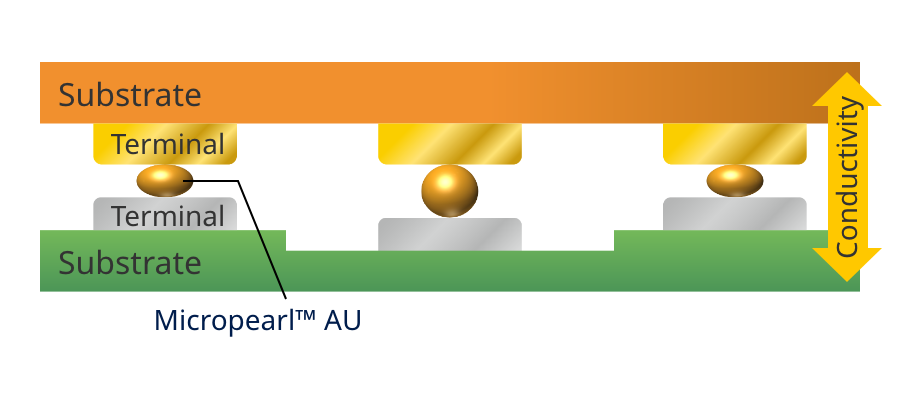

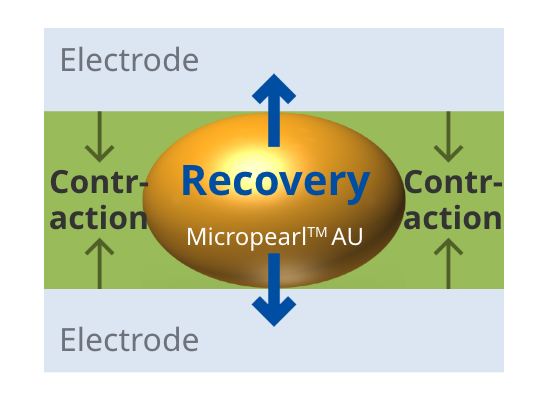

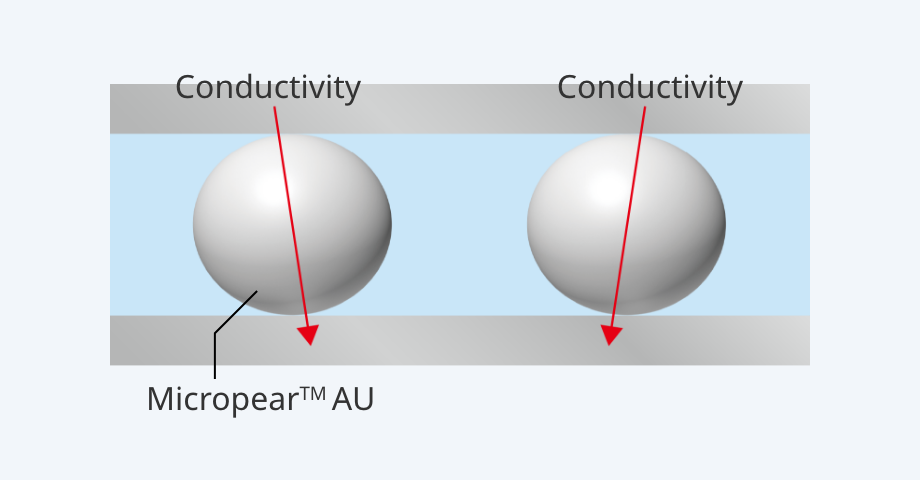

Mechanism of electric conduction and connection reliability

Due to its resilience and binder contraction force, Micropearl™ AU makes contact with and keeps close contact with the electrode. As a result, it contributes to stable electric conduction.

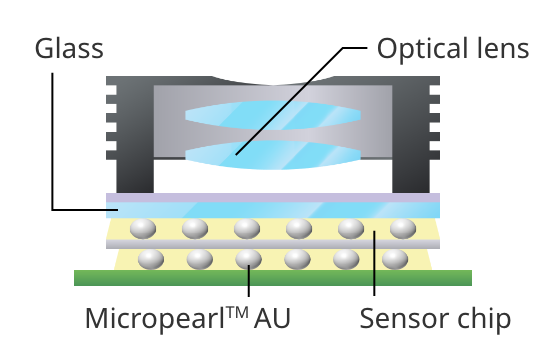

Capable of uniformly controlling the adhesion layer, liquid layer, or space thickness in an easy manner.

Ensures flatness and parallelism / reduces inclination due to curing shrinkage (improvement of reliability) / prevents optical axis deviation / evenly distributes heat radiation and stress dispersibility sensor sensitivity etc.

E.g.) Multilayer chips / optical components / sensors / liquid crystal materials / communication module-related bonding / glass bonding, etc.

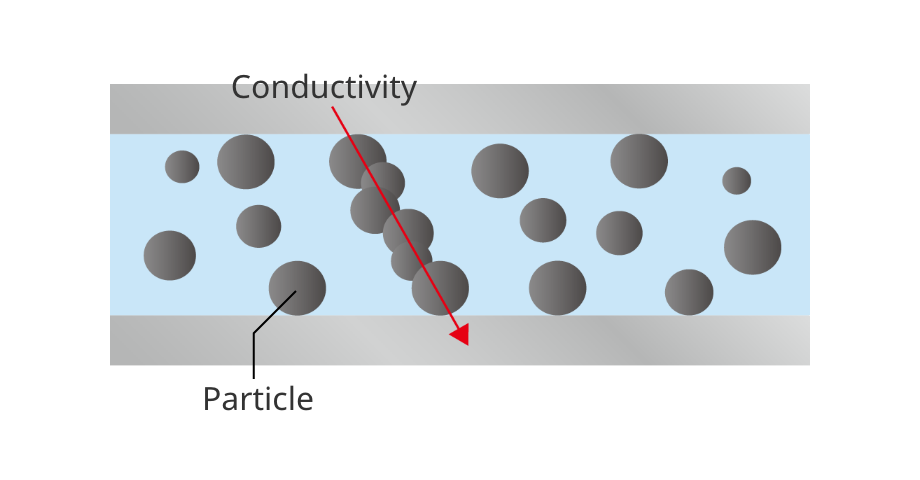

Use as electromagnetic shield

Challenge

As the general vehicle safety improves and automatic driving technologies are increasingly employed, the number of employed ADASs is anticipated to increase, and the number of various control systems is also anticipated to increase due to the shift towards EV.

On the other hand, those devices are recognized to pose serious risks of performance degradation and system stop due to electromagnetic interference among them, and the number of cases in which resin case is provided with electromagnetic shielding effect is anticipated to increase. However, for example, the manufacturing method of producing ordinary resin case and then applying metal coating poses a concern about increase of processes and a challenge of increased vehicle weight.

SEKISUI's Solution

- With pre-molding resin pre-kneaded with conductive MicropearlTM AU, the electromagnetic shielding effect is anticipated to be provided only by performing the normal molding process.

- MicropearlTM AU, which has a low specific gravity, enables easy dispersion in resin, and is anticipated to help reduce the increase of vehicle weight.

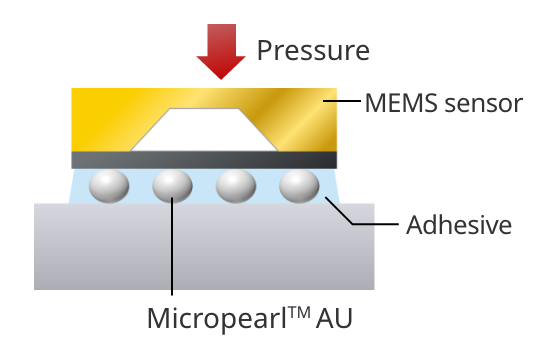

Conductive adhesion between different materials

Challenge

In recent years, the need for bonding between different metals and various materials for many applications has been highlighted.

In particular, in order to bond metals at a large area while maintaining conductivity between them, a strong force or heat is generally required, which poses a concern about breakage of thin metal foil or generation of pin hole.

To address this issue, bonding metals with conductive adhesive may be considered as an easy adhesion method. However, the thickness control may be difficult, or filler in large amount may be added in order to secure the conductive portions.

SEKISUI's Solution

- Addition of uniform Micropearl™ AU with the same size as the target film thickness in a minimum amount is anticipated to achieve vertical conductivity with a high probability.

- Addition in minimum amount contributes to the maintenance of adhesive force and the retention of formability.

- Appropriate setting of addition amount is also anticipated to provide a spacer function.

- Due to its low specific gravity, Micropearl™ AU can be uniformly dispersed through easy kneading.

Metal Types Lineup

Representative metal types

- Characteristics

-

- Hard metals

- Ferromagnetism

- Characteristics

-

- High reliability

If you desire other metal types, please feel free to consult with us.

- These colors are for illustrative purposes only. The actual colors may be different.

Comparison in hardness control

Plastic particles and metal film control allow adjustment of hardness and recovery rate.

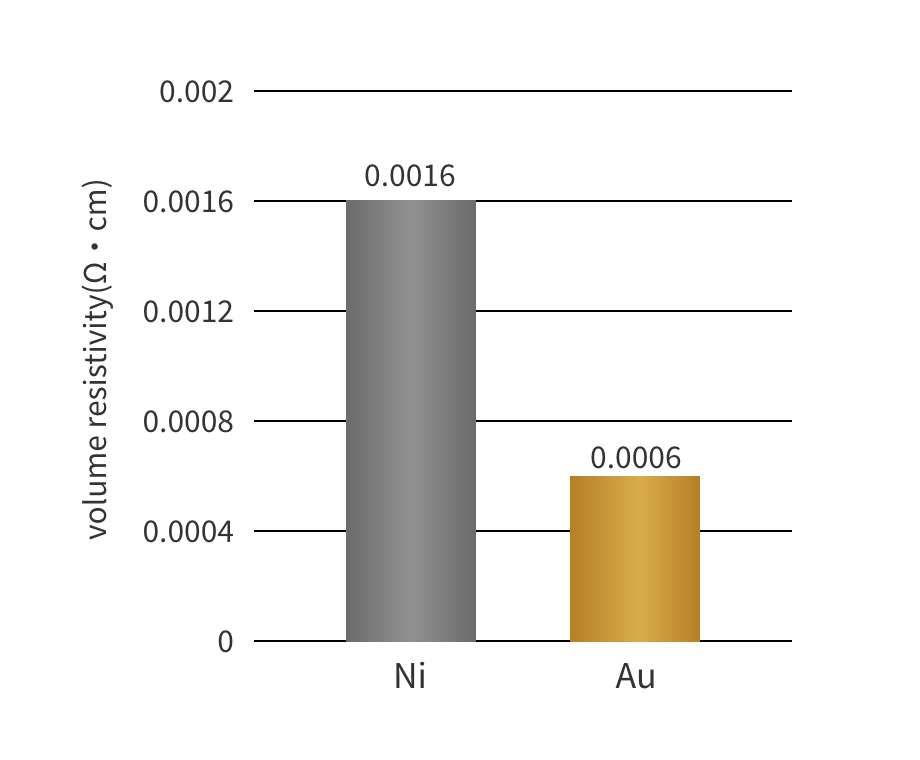

Comparison in volume resistance

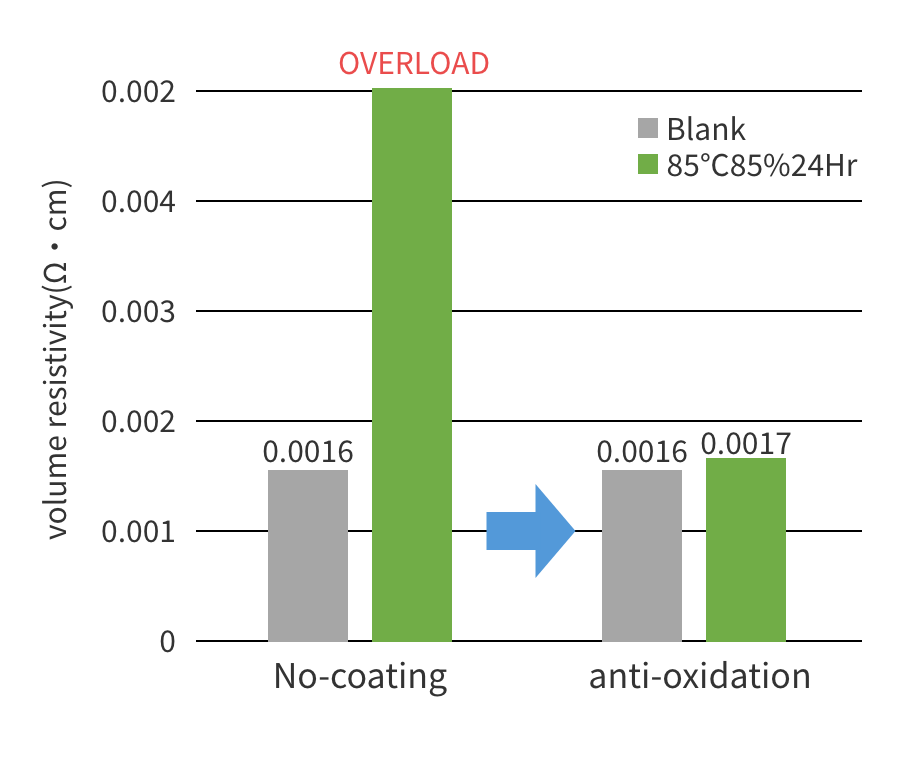

Anti-corrosion treatment effect of Ni coating

- Evaluation reference value based on resin core of 10 μm

- The above is not the standard value. This varies depending on the particle size and metal film thickness.