- Top Page

- Enjoy SEKISUI's Core Technology

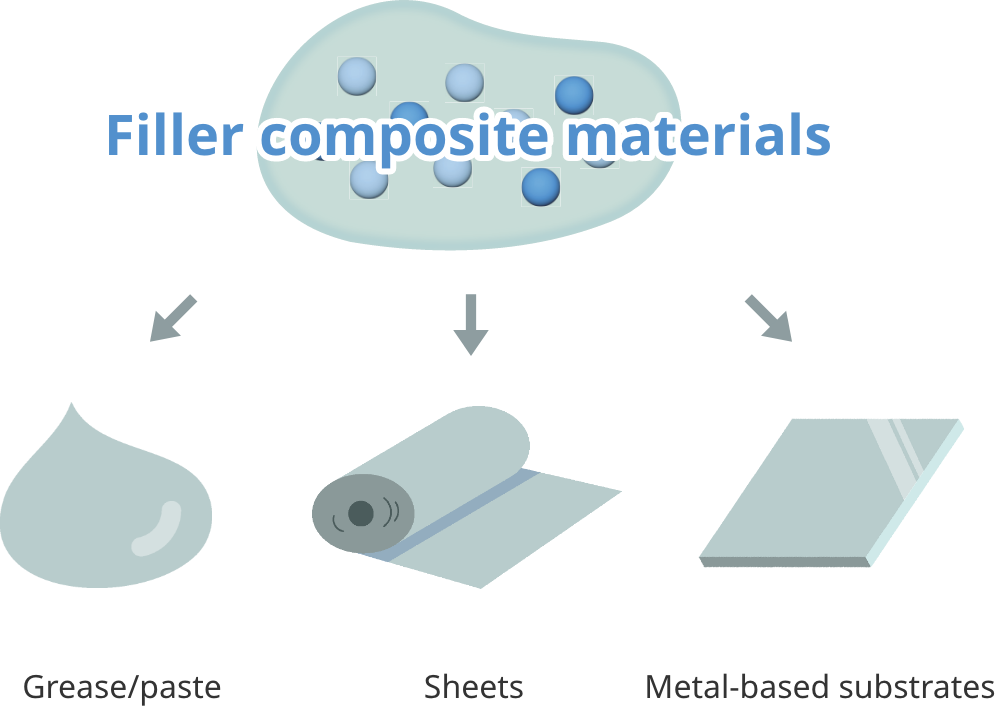

- Filler composite materials

Completed by combinations of two materials:

pair skaters.

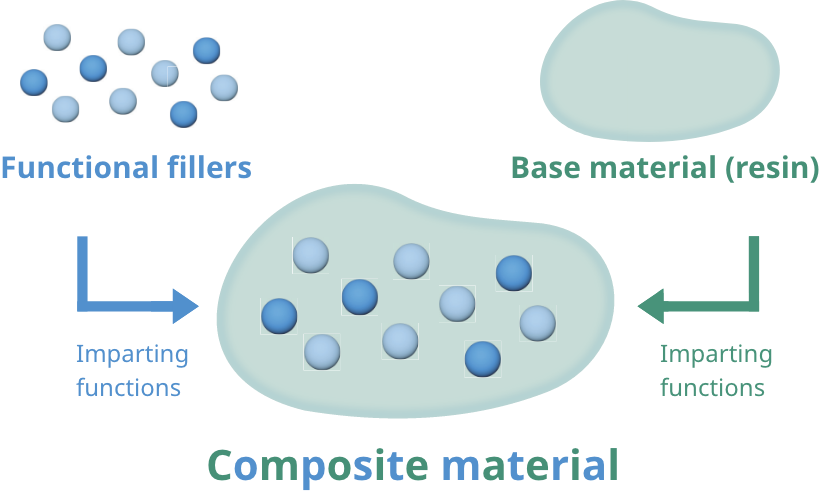

What is a filler composite material?

Highly functional plastics containing fillers

A filler refers to a filling material.

Fillers that have various functions, such as thermal conductivity and electrical conductivity, are compounded with resins to formulate highly functional plastic materials that surpass the conventional limits.

Properties

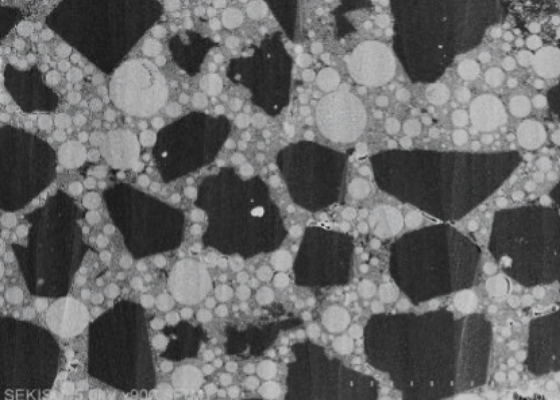

Mixing fillers into resins to create a single material

Complementary functions and properties that cannot be achieved by a single material

A resin, which is used as the base material, is lightweight and easy to form.

Compounding with fillers that have various functions makes it possible to offer composite materials that take advantage of respective materials.

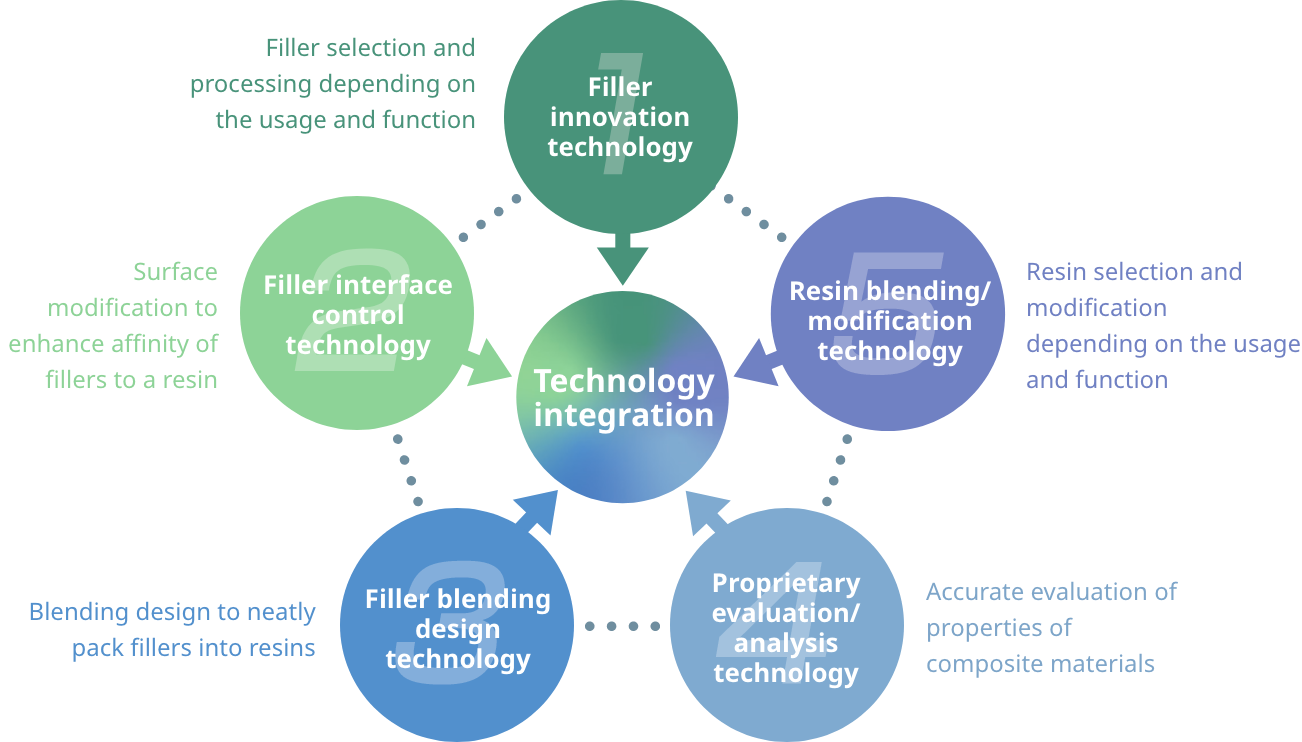

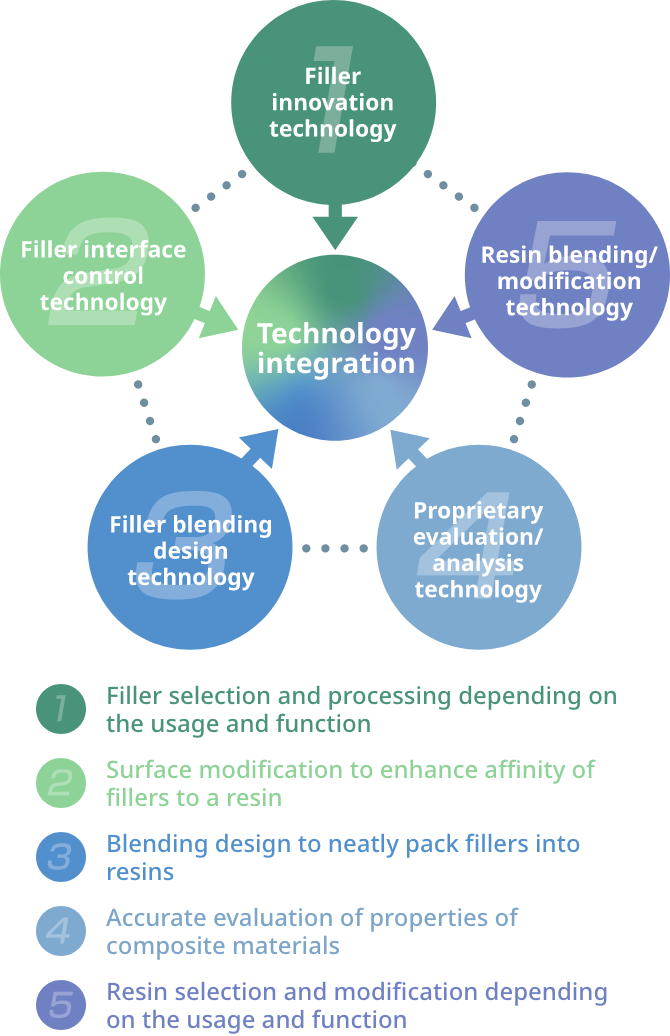

Key to SEKISUI CHEMICAL’s filler composite technology

We will introduce technologies for offering highly functional composite materials.They include selection of fillers and resins, surface modification to enhance affinity of fillers to resins, blending designs to achieve closest packing of fillers to resins, and accurate evaluation of properties of composite materials created.

Familiar products in which filler composite materials are used

From bathtubs to aircraft

Filler composite materials are used for various applications, including home-use bathtubs, smartphones, railroad ties, and aircraft, due to their functionality, such as heat resistance and high strength, making our daily lives and social activities comfortable.

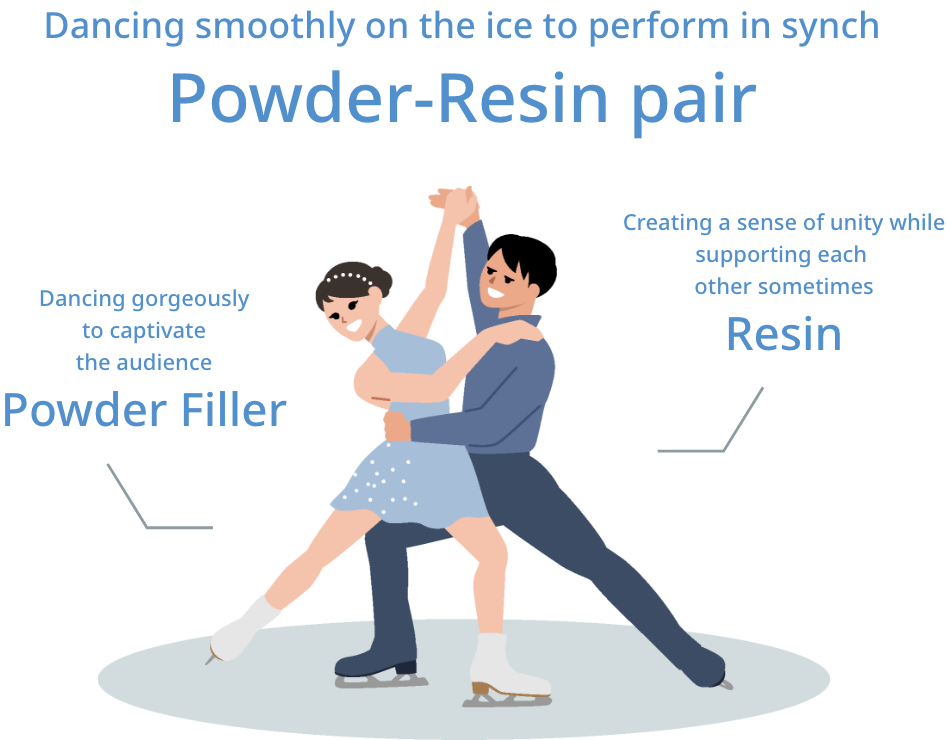

Filler composite materials are similar to pair skaters.

Pair skaters skate on the ice in splendid combinations.

They skate smoothly on the ice to demonstrate performances and support each other based on mutual trust. They are akin to filler composite materials. We will explain filler composite materials, which are completed by combinations of two materials, in analogy to pair skaters.

8 main functions

Thermal conductivity

Smoothly transmitting and releasing generated heat

The Powder-Resin pair can warm them up quickly and demonstrate high performance in the competition. The heat of the warmed-up bodies can be released outside to cool down promptly.

Fillers with high thermal conductivity release heat and prevent the increase in the operating temperature of electronic devices, thereby contributing to a comfortable IoT society.

Electrical conductivity

Electroconductive to transmit electricity effectively

The Powder-Resin pair transmits electricity by skating with a lightness of step, just like lightning.

Composite materials containing electroconductive fillers, such as metals, are used for antistatic materials and electroconductive rubber materials for sensors, etc.

Strength

Resistant to physical impact and will not break

The Powder-Resin pair has strong bodies and ties to successfully perform any difficult techniques.

The resin uniformly distributes physical pressure and absorbs impact. Thus, it demonstrates high impact absorbing performance. Composite materials with high mechanical strength can be offered by adding fibrous fillers, etc. to resins.

Light shielding performance

Dressed in black to block light

The Powder, which is dressed in black, absorbs and blocks light.

The carbon black material and structure characterized by high light absorbing performance demonstrate excellent light shielding performance.

Heat resistance

Resistant to heat and will not melt

The Powder-Resin pair can withstand heat that melts the skating rink and does not give up.

Fillers are strongly bonded with resins and prevent resins from melting or being decomposed due to heat, thereby improving heat resistance.

Flame retardance

Heat-resistant and will not burn

The Powder-Resin pair is resistant to blazing flames and demonstrates a passionate performance even in a hyped venue without any problem.

Composite materials containing flame-retardant fillers are fire-resistant and less likely to burn, thereby enhancing fire safety of various buildings and structures.

Gas barrier performance

Repelling various gases and preventing transmission

The steps of the Powder-Resin pair are characterized by a regular rhythm and rotation and repel oxygen and other gases.

Ingress of gases is prevented by arranging fillers with special shapes, such as sheet-like fillers. Applications include food wrap films that do not transmit oxygen.

Adhesiveness/

flexibility

Soft bodies that fit perfectly!

The Powder-Resin pair performs stretching every day and captivates spectators with flexible bodies that can perfectly keep any complicated poses.

Highly flexible filler composite materials can adapt to any uneven surfaces (shapes) and have high adhesiveness.

Applications of filler composite materials

Filler composite materials are formed into various shapes and used as heat release materials.

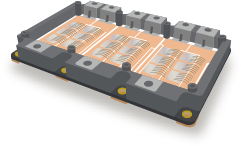

Releasing heat from inside the batteries for electric vehicles

To ensure the life, safety, and stable performance of batteries for electric vehicles (EVs), filler composite materials help temperature control of batteries. Heat is generated through charging and discharging cycles, which may cause deterioration and fire. It is necessary to release heat from inside batteries and maintain an appropriate temperature.

Functions

Thermal conductivity

Heat resistance

Adhesiveness/flexibility

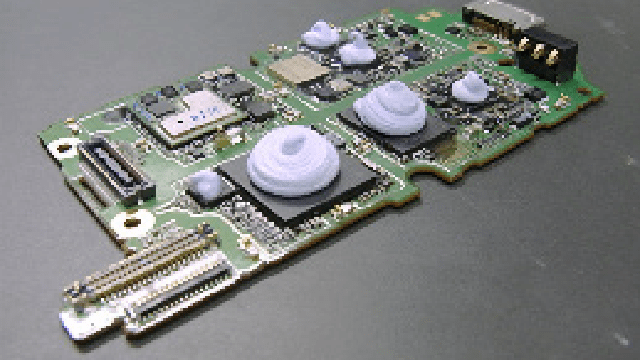

ICs for driving high-resolution TV sets

Filler composite materials are used for heat management of high-definition TV sets, such as 4K/8K TV sets. Suppression of temperature rise while driving ICs contributes to a comfortable video watching experience using high-definition TV sets, such as 4K/8K TV sets.

Functions

Thermal conductivity

Adhesiveness/flexibility

Heat release materials that release heat from electronic devices

Filler composite materials are used as heat release materials that release heat from devices, including smartphones. Highly flexible heat release materials are characterized by excellent adaptability to uneven surfaces. They are effective for collective heat management of substrates on which various parts are mounted.

Functions

Thermal conductivity

Adhesiveness/flexibility

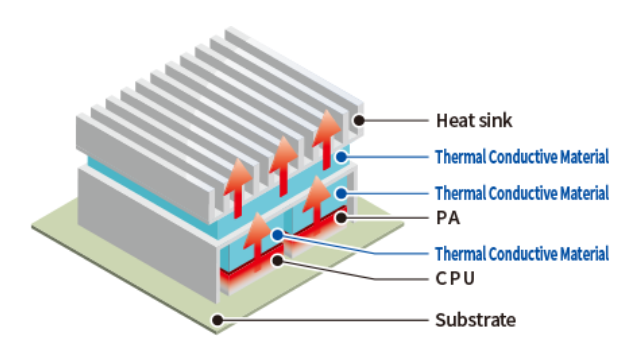

Heat release materials that release heat generated when driving semiconductors

Filler composite materials are used to release heat generated when driving semiconductors. The use of heat release sheets with high thermal conductivity, which can maintain flexibility, adhesiveness, etc. of polymers, makes it possible to cool parts that generate high heat, such as CPUs, GPUs, and high-energy-density LEDs.

Functions

Thermal conductivity

Adhesiveness/flexibility

Contribution of filler composite materials to society

Contribution to telemedicine, automated driving, and entertainment

through improvement of the semiconductor driving performance

Penetration of IoT

to daily lives

by achieving high-speed communication, multi-point connection, and energy conservation at data centers

Increasing the use of

EVs (rapid charging) and using EVs as part of infrastructure

through DC-AC switching and reduction of energy loss

Introduction of products

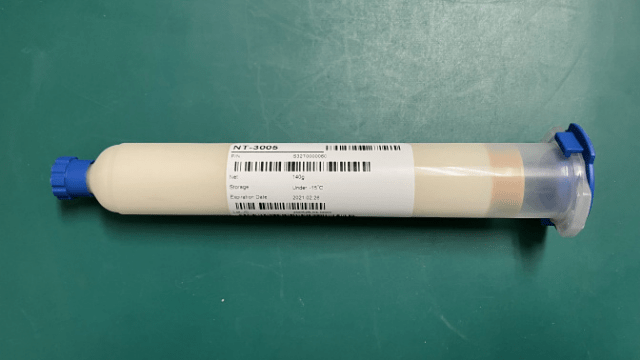

Thermal paste/grease

The flexible silicone-free thermal paste materials are applied on heat-generating components and cured in an oven. This enables bubble-free molding. Thermal radiation into the air enables easy dissipation of heat from heat-generating components.

Thermal grease (one-component/two-component)/non-adhesive materials

SEKISUI’s grease is characterized by excellent reworkability because it is non-adhesive. We offer one-component and two-component types. Appropriate products are available depending on the usage.

![1-Part Heat-Curable Grease[Adhesive thermal conductive grease]](../../common/images/technology/filler/sec_usage-products_03_03.png)

1-Part Heat-Curable Grease

[Adhesive thermal conductive grease]

This product combines excellent thermal conductivity and low elasticity, and develops adhesion through heat curing. Note that this product should be stored frozen.

Features

- High thermal conductivity and good molding properties

- Highly flexible and applicable to flexible substrates

- Applicable to various application processes to automate the processes

![1-Part Silicone-free Thermal Conductive Grease[GA Series]](../../common/images/technology/filler/sec_usage-products_03_04.png)

1-Part Silicone-free Thermal Conductive Grease

[GA Series]

This silicone-oil-free product does not cause such problems as contact failure due to low molecular siloxane.

Features

- Grease type, silicone-free

- Easy to handle and to dispense and apply to substrates

![2-Part Thermal Conductive Gap Filler[CGW™Series]](../../common/images/technology/filler/sec_usage-products_03_05.png)

2-Part Thermal Conductive Gap Filler

[CGW™Series]

The CGW™ series is two-component room-temperature-curing silicone thermal grease. The processes can be automated by using packing equipment.

Features

- Solvent-free, two-component type with excellent stability

- Thick buildup made possible by high thixotropy

- Also used for automotive control parts and batteries due to high durability

Heat release sheets

The heat release sheets demonstrate high thermal conductivity while maintaining flexibility by harnessing proprietary filler orientation technology. We offer a wide variety of heat release sheets, such as silicone-free and insulating sheets, which are used for various devices.

Super Thermal-Conductive Pads

[MANION™ Series]

The heat release sheets achieve flexibility, adhesiveness, and other features by harnessing the high thermal conductivity of carbon fibers based on magnetic field orientation technology.

Features

- A grade focused on thermal conductivity compared to the double-faced adhesive type

- Achieving thermal conductivity of up to 25 W/(m・K) while ensuring flexibility

- Resistant to low temperature (−40°C), high temperature (150°C), humidity, and heat cycles

Thermal-Conductive Pads

[TIMLIGHT™ Series]

These products are low-siloxane silicone sheets. They demonstrate high thermal conductivity by adapting to heat-generating devices due to their flexibility and adhesiveness while harnessing excellent temperature durability and electrical insulation derived from silicone.

Features

- Excellent temperature durability and electrical insulation achieved by silicone

- High thermal conductivity by harnessing flexibility and adhesiveness

![Thermal-Conductive Pads[TIMLIGHT™ High Thermal Conductive Series]](../../common/images/technology/filler/sec_usage-products_04_03.png)

Thermal-Conductive Pads

[TIMLIGHT™ High Thermal Conductive Series]

The heat release sheets are characterized by high thermal conductivity with carbon fibers oriented in the Z direction.

Features

- Double-faced adhesive type that retains adhesiveness derived from polymers

- Excellent mountability and adaptability

![Thermal-Conductive Pads[TIMLIGHT™ Soft Series]](../../common/images/technology/filler/sec_usage-products_04_04.png)

Thermal-Conductive Pads

[TIMLIGHT™ Soft Series]

The heat release sheets are highly flexible. The heat resistance value during assembly was successfully minimized by focusing on adhesiveness to devices and compressibility.

Features

- Adaptation to uneven surfaces and cushioning performance by taking full advantage of the flexibility of the base material

- Effective for designs, such as ensuring adhesion to parts of different height, reducing stress to substrates, and absorbing tolerances

![Heat Release Electromagnetic Wave Absorbing Sheet[Heat Release & EEM Wave Absorbing Sheet Pμ]](../../common/images/technology/filler/sec_usage-products_04_05.png)

Heat Release Electromagnetic Wave Absorbing Sheet

[Heat Release & EEM Wave Absorbing Sheet Pμ]

The heat release electromagnetic wave absorbing sheets feature excellent electromagnetic wave absorbing performance while maintaining the flexibility and thermal conductivity of the heat release sheets. A single sheet can cope with electromagnetic noise and heat generated in electronic devices.

Features

- Can protect against both heat and electromagnetic waves

- Can protect against noise only by pasting a sheet to the target area

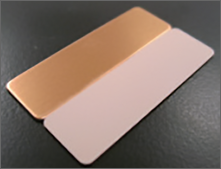

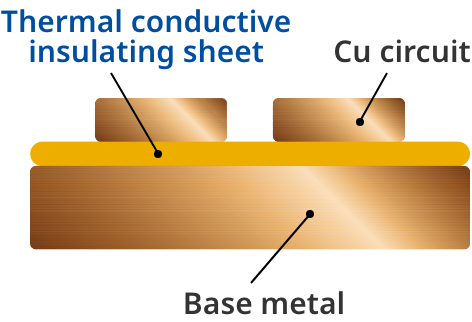

Thermal conductive insulating sheet

These heat release materials can be applied to power devices, etc. Both high thermal conductivity and high electrical insulation are realized by high density packing of fillers with excellent thermal conductivity. Ceramic substrates can be replaced due to high reliability.

![Thermal conductive insulating sheet [Insulated Metal Substrate 「NF-type」]](../../common/images/technology/filler/sec_usage-products_05_02.png)

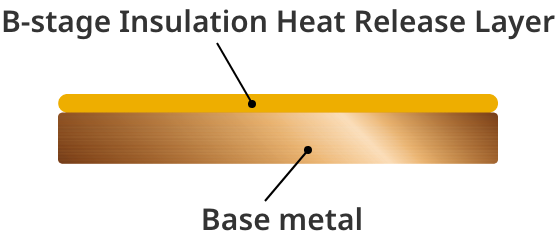

Thermal conductive insulating sheet

[Insulated Metal Substrate 「NF-type」]

The substrates have an adhesive (heat-curing) insulation layer in the B-stage condition and are characterized by high thermal conductivity and excellent electrical insulation. It is possible to combine them with various kinds of materials of diverse thicknesses due to excellent sheet properties and adhesiveness.

Features

- Heat release materials characterized by high thermal conductivity and excellent electrical insulation

- Excellent heat resistance, high adhesiveness, and high reliability

Examples of usages

Product overview

| Product | Resin Substrate with B-stage layer | Thermal conductive insulating sheet |

|---|---|---|

| NF-type | Insulating sheets for metal-based substrates | |

| Overview |  |

|

| Product Composition |  |

|

| Examples of usages |

IPM module

|

IGBT module

|