- Top Page

- Enjoy SEKISUI's Core Technology

- Fine partcles

Fine particles demonstrate great performance

in sync, analogous to 'artistic swimmers.'

What are fine particles?

Micron-sized tiny spheres

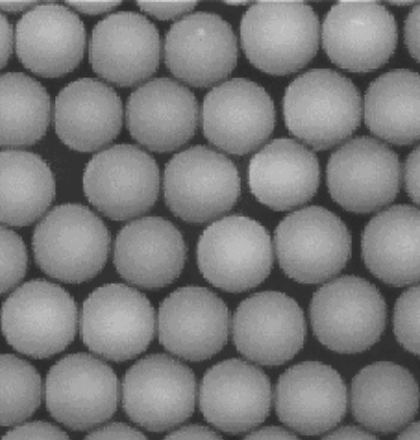

Fine particles appear to be powder, but they are micron-sized tiny spheres. The uniform size enables gap control to ensure uniform height.

Fine particles are also characterized by large surface areas. Depending on the usage, functions are imparted to fine particles, which are mainly used for gap control of automotive parts and optical parts.

Properties

Any materials can be turned into tiny particles

Any materials, including soft silicone resins, hard acrylic and epoxy resins, and silica, can be turned into micron-sized (1/1,000 mm) spheres.

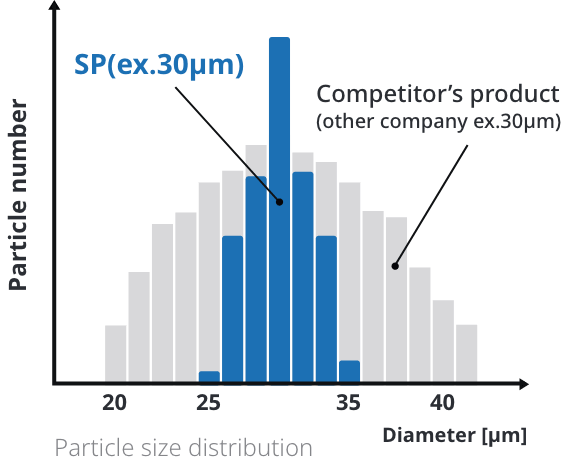

Capable of standardizing the size

SEKISUI CHEMICAL’s proprietary polymerization and classification technologies make it possible to select only the finest particles and produce resin spheres of the uniform size in microns or millimeters. The products are characterized by excellent uniformity compared to competitors’ products.

Familiar products in which fine particles are used

For paper clay, shoe soles, smartphones, etc. at home

At home, fine particles are used for paper clay, spongy parts of shoe soles, etc., as well as liquid crystal displays and other internal parts of smartphones, etc. Many fine particles are imperceptibly used for products around you.

Fine particles are similar to teams of artistic swimmers.

Artistic swimmers compete for beautiful performance in teams.

This sport features fluid forms and synchronized movements of artistic swimmers who demonstrate beautiful and dynamic skills. The swimmers are akin to fine particles.

10 main features

Thickness retention performance

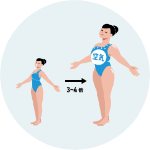

Capable of achieving uniform thickness of resins

Artistic swimmers make a grand entrance to the poolside, perfectly synchronized in height and step.

Mixture of fine particles whose size and shape are uniform makes it easy to keep the thickness of liquids and spaces uniform.

Resilience

Regaining its spherical shape after being compressed

Artistic swimmers work together to immediately return to the previous formation after converging at the center.

Thanks to resilience, plastic fine particles return to the original size after being compressed, just like rubber. They are not fatigued no matter how many times they are compressed.

Electrical/

thermal conductivity

Electroconductive and thermal-conductive by coating metals

Artistic swimmers in glossy swimwear are electroconductive and sometimes release heat. Metal-coated plastic fine particles serve as contact materials between electrodes and as heat release materials, too.

Property to impart convexities

Preventing films from sticking together

Artistic swimmers extend their legs out of the water to repel objects.

Fine particles on a film serve as convexities and reduce the film area that comes into contact to prevent sticking. Applications include anti-blocking agents.

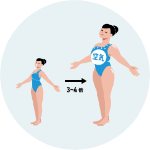

Foaming performance

Becoming lighter due to expansion like a balloon

Before getting into the pool, artistic swimmers can make their bodies larger and lighter by accumulating air in their bellies.

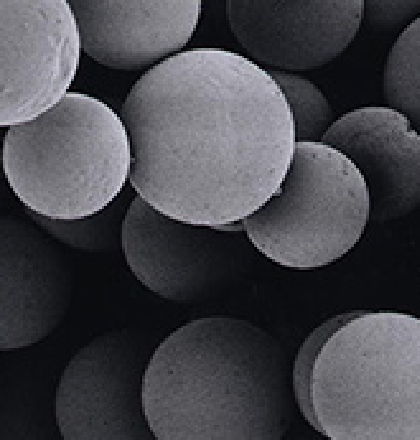

When a fine particle that contains low-boiling-point substance in its core is heated, the shell becomes soft, causing it to expand by three or four times in diameter.

Pore forming performance

Creating cavities of a uniform size to capture harmful substances

Artistic swimmers are uniformly dispersed in water and turn into air.

Fine particles of a uniform size are dispersed in resins or ceramics and sintered or dissolved to form cavities in a uniform size to capture soot, dust, and other particles.

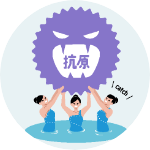

Trapping/

agglutination performance

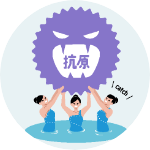

Capturing antigens by using special hands

Artistic swimmers can capture and lift antigens by using special hands.

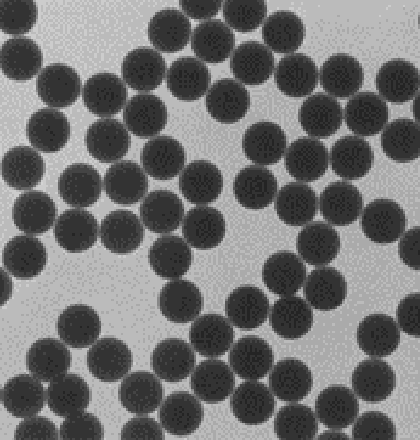

The surface area of fine particles is large. Thus, antibodies can be imparted to the surface to capture antigens. A small amount of fine particles can capture many antigens.

Light shielding performance

Blocking black light by coloring them black

Artistic swimmers in black swimwear absorb and block black light.

Transparent plastic fine particles turn black by containing pigments, including carbon, making it possible to block light. Such particles demonstrate their performance around lenses and for displays, etc.

Transparency

Can be made invisible in resins or liquids

Artistic swimmers appear transparent in water.

Fine particles become invisible by matching their refractive index with that of substances around them. They demonstrate their performance in transparent adhesives and tapes, etc.

Strain relaxation performance

Absorbing force and flexibly adapting to deformation

Because of their flexible bodies, artistic swimmers can deform freely against any forces.

Flexible plastic fine particles dispersed in resins can absorb external forces, making resins resistant to damage when subject to forces or strains.

Applications of fine particles

Adjusting the thickness of liquid crystal displays as liquid crystal spacers

Fine particles are used as thickness adjustment materials (spacers) to achieve uniform thickness of liquid crystals for smartphones, etc. They eliminate display uniformity issues caused by differences in thickness, realizing clear images. Light shading is possible by turning the particles black, achieving high-contrast LCD image quality.

Features

Thickness retention performance

Resilience

Light shielding performance

Connecting electrodes in smartphones to transmit electricity

Metal-coated fine particles are used to transmit electricity by connecting tiny electrodes around displays and sensors in smartphones.

Metal-coated fine particles are mixed into adhesives and tapes. Electricity can be transmitted only by joining electrodes using such adhesives and tapes.

Features

Thickness retention performance

Resilience

Electrical conductivity

Preventing the inclination of adhesive joints of chips in electronic devices

Fine particles of a uniform size are used for bonded joints of chips in electronic devices. If a chip is inclined, stacking causes the inclination to increase, making accurate wiring impossible.

The inclination of chips is prevented by mixing fine particles in adhesive joints to enable accurate assembly of devices.

Features

Thickness retention performance

Resilience

Strain relaxation performance

Lightweight and highly durable foams for wallpapers, shoe soles, and automotive components

Thermo-expandable fine particles are used as foams for cushions of wallpapers and shoe soles and automotive sealing materials.

The weight reduction performance is excellent because the air volume can be increased. Durability is also superb because the fine particles have shells unlike general chemical foaming materials.

Features

Foaming performance

Pore forming performance

Strain relaxation performance

Capturing antigens as latex in diagnostic drugs for tests

Fine particles are also used in diagnostic drugs for disease testing.

Fine particles equipped with antibodies on their surface quickly react to antigens, which are foreign matter that enters the body. A single antigen is captured by multiple antibodies, causing fine particles to agglutinate and precipitate. Disease diagnosis is conducted based on their precipitation patterns (turbidity).

Features

Trapping/agglutination performance

Coloring performance

Anti-blocking agents for films

Films get stuck in a roll form, making it difficult to remove. Sticking of films can be prevented by embedding fine particles in films and providing tiny convexities on the film surface.

Features

Property to impart convexities

Transparency

Introduction of products

Micropearl™ series

Plastic particles with uniform particle size distribution.

They can be used for various applications, such as gap formation in automotive and optical parts.

ADVANCELL EM

Thermo-expandable microspheres (tiny plastic spheres) containing a low-boiling-point hydrocarbon inside thermoplastic polymer cells.

Latex for tests

Diagnostic agents that use agglutination between antibodies and target substances (antigens).