Sustainability Products

Sustainability Products

We provide a wide range of functional chemicals

that contribute to reducing environmental impact and

conserving resources and energy.

Sekisui Chemical’s climate change measures and

new GHG emission reduction targets

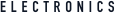

Sekisui Chemical recognizes that climate change is a major social issue and also a major risk for our group, and we are actively working to resolve it. In 2018, we became the first company in the chemical industry to obtain SBT certification, and in October 2022, as climate change countermeasures become an even more pressing social task, we established new GHG emissions reduction targets.

| Conventional target | Updated target | Means of achieving updated targets | |

|---|---|---|---|

| Scope 1+2 | Base year: 2013 Target year: 2030 Reduction rate: 26%(2°C target) |

Base year: 2019 Target year: 2030 (no change) Reduction rate: 50% (Equivalent to 1.5°C target) |

In addition to the conventional move, shifting to renewable energy of purchased electricity, we will accelerate efforts to reduce fuel-derived GHG through a shift to low-carbon fuels, electrification, and production innovations. |

| Scope 3 | Base year: 2016 Target year: 2030 Reduction rate: 27% (2°C target) |

Base year: 2019 Target year: 2030 (no change) Reduction rate: 30%(Equivalent to WB 2°C target) |

Added resource recycling initiatives (shift to non-fossil raw materials, expanded use of recycled materials, recycling of waste) and promoted reduction of waste of raw materials and sold products and business waste |

Measures to achieve Scope

Scope 1+2

Conversion to low-carbon fuels

To achieve our Scope 1+2 targets, we will continue to promote activities to increase the renewable energy ratio of purchased electricity and will aim to achieve 100% by 2030. From 2023, we will proceed with the electrification of fuel-using equipment and shifting to low-carbon fuels. We will also work ahead of schedule to reduce energy consumption through shifting to steam sources, which are technically difficult, and the innovation of production processes. We plan to invest a total of 40 billion yen by 2030 in capital investment and renewable energy procurement that will contribute to reducing GHG emissions in Scope 1+2.

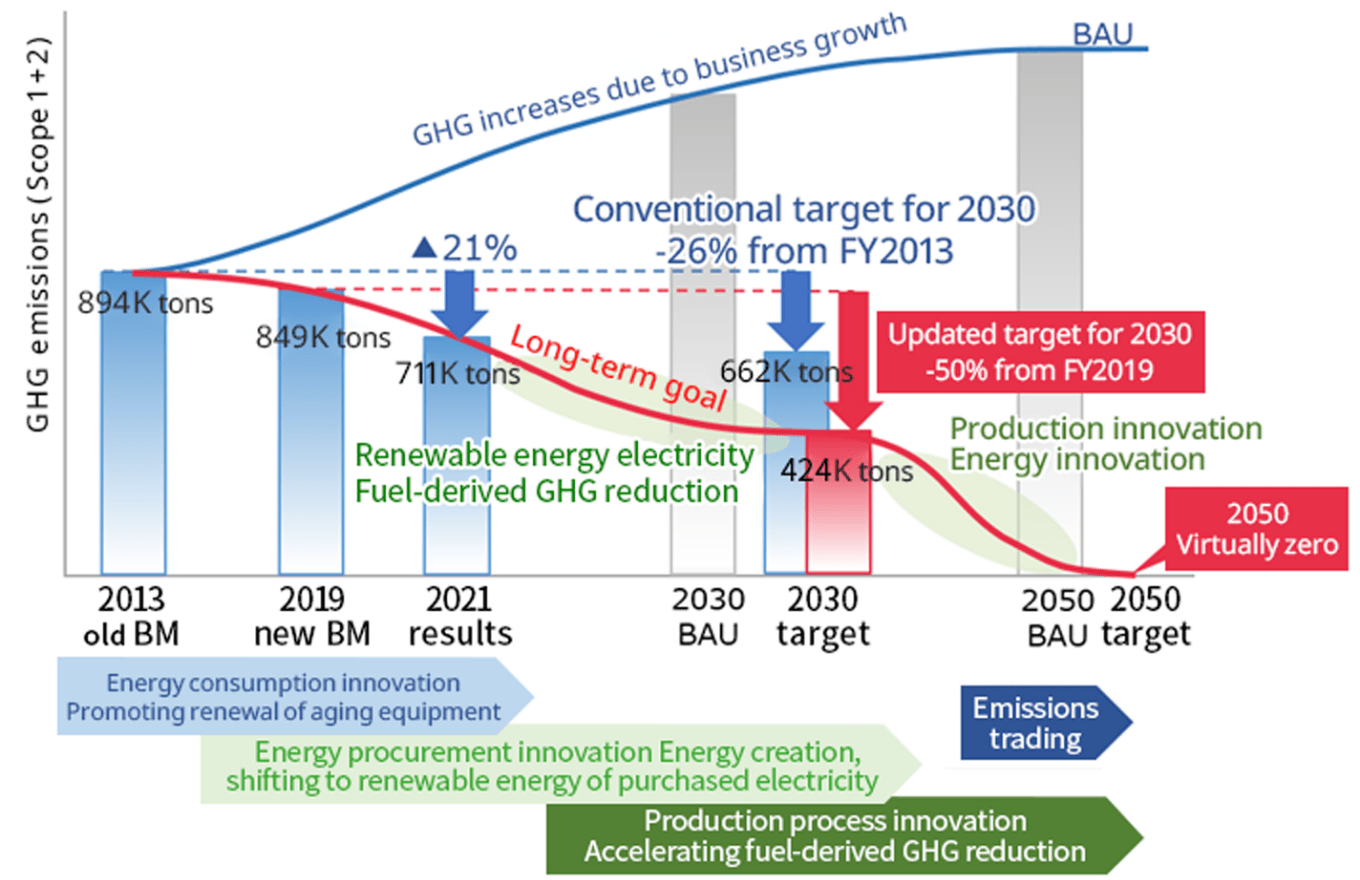

Scope 3

Initiatives for resource circulation

We will promote Scope 3 reduction through resource recycling initiatives. Specifically, we will shift from resin raw materials, which account for 50% of purchased products and services, to non-fossil-derived materials and expand the use of recycled materials. This will also lead to a reduction in GHG emissions from the disposal of sold products. We will also promote the recycling of waste plastics and make new efforts to reduce waste generated from our business.

*Quoted from Sekisui Chemical Co., Ltd.『 New SBT Certification Obtained for Greenhouse Gas Reduction Target of 1.5°C 』

Thoughts on achieving sustainability

Sekisui Chemical Electronics’ measures to reduce GHG emissions

In order to reduce the burden of contributing to the environment, Sekisui Chemical has declared that it is taking on the challenge of achieving carbon neutrality, aiming for zero GHG emissions by 2050, which is a high hurdle for a chemical manufacturer, as well as realizing a circular economy to minimize fossil resource consumption by 2050.

Developer’s thoughts on developing products that reduce GHG emissions

Please take a look at the developer’s thoughts on reducing GHG emissions, from the product development planning stage to launch.

Environmentally friendly products

in the electronics field provided to customers

| Environmentally contributing product name |

Product description and environmental contribution points | |

|---|---|---|

| Bio-based tape | By using plant raw materials that do not violate forest destruction, food competition, and illegal labor, this tape achieves 73% bio-derived content and exhibits performance equal to or higher than that of conventional petroleum-derived products. It can contribute to the realization of a sustainable society, such as reducing oil consumption, reducing CO₂ emissions, improving the ratio of renewable materials, and SDGs, and has a variety of lineups depending on the type of substrate and product composition. PET tape can be used to fix parts of various electronic products and to light shield displays, and recycling PET is used on substrates and release liners to further reduce CO₂ emissions. Foam tape can be used as a fixing material for applications that require water resistance, impact relief, and cushioning of various electronic products. | |

| Inkjet | By adjusting the photoreactivity and viscosity of the inkjet material to the utmost limit, we have made it possible to apply high-resolution patterns on substrates that are difficult to wet and spread. Compared to a photolithography process in which photoresist is coated on the entire surface of a substrate and then developed/patterned using a photomask, for example, coating a grid shape (10 mm size) with a width of 100 μm can achieve a material reduction of approximately 95%. |

|

| Photolec™ series | The Photolec™ series is a special adhesive mainly used for energy-saving display devices (LCD, OLED). All products are VOC-free and can be cured using UV energy and low temperature (or room temperature curing), which reduces energy consumption in the manufacturing process and contributes to reducing environmental impact. | |

| Micropearl™ AU | Micropearl™ AU is a conductive material in which the surface of plastic particles is coated with metal, and conduction can be achieved by contacting an electrode. The amount of metal used can be reduced by more than 50% compared to pure metal powder. Furthermore, there are concerns that gold will be depleted around the world, and reducing the amount of metal will contribute to the survival of metal resources. |

External evaluation

“2023 Global 100 Most Sustainable Corporations in the World index”

Ranked 84th among the 100 most sustainable companies in the world

Selected for DJSI (Dow Jones Sustainability Indices)

“World Index”

Re-certified with the “SBT (Science Based Targets) Initiative”

for the GHG reduction target of 1.5°C (March 2023)

Received the Silver Award in the Environmentally Sustainable Company Category at the 3rd ESG Finance Award Japan

In order to make limitless contributions to

the earth and society,

Sekisui Chemical pursues sustainability

in its company and supply chain and with customers.