Release Film for Heat Press Process

(Low Outgas Release Film)

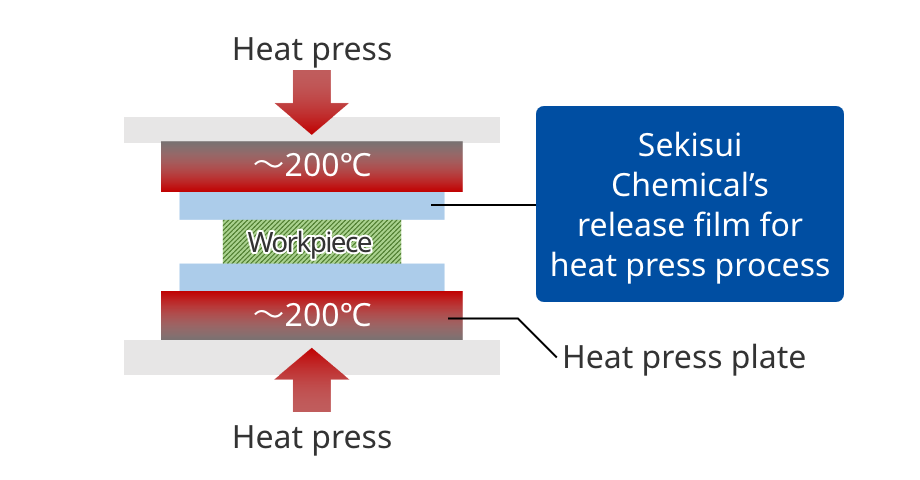

What is Sekisui Chemical's release film for heat press process?

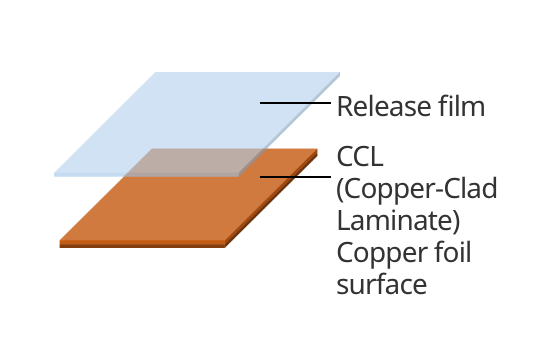

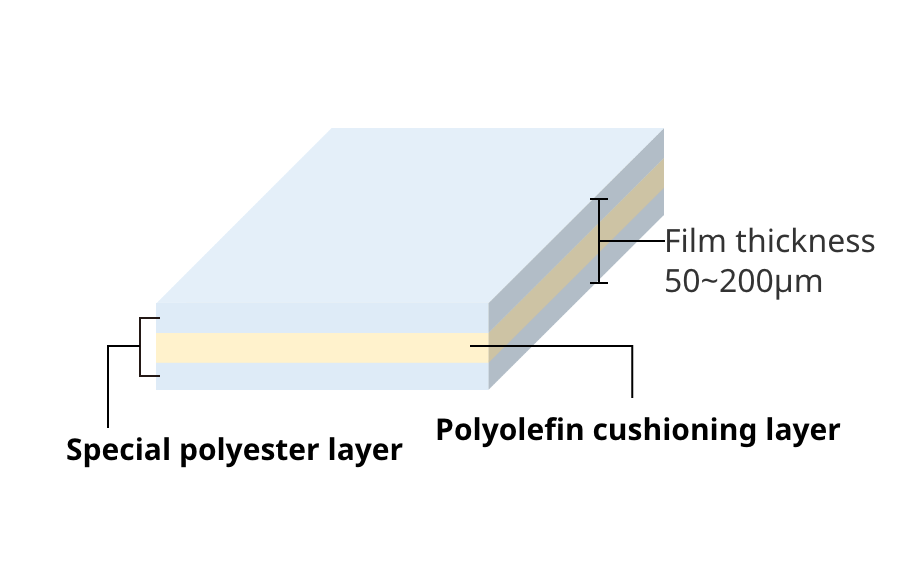

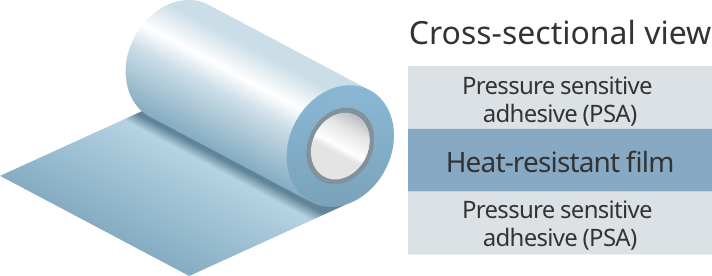

Sekisui Chemical's release film has a multi-layer structure consisting of special polyester layers and a polyolefin cushioning layer, and is widely used for surface protection and buffering in heat press processes.

Multi-layer structure of the release film

- Special polyester layer

-

Function

Provide resistance to heat press at a wide range of temperatures, and high release performance from the object

-

Material

Designed to minimize outgassing during heat press and prevent contamination

- Polyolefin cushioning layer

-

Function

Provide flexibility to the film, allowing it to easily conform to the shape of the object

The film structure is customizable based on your requirements.

Consult our experts to find the best solution for your needs.

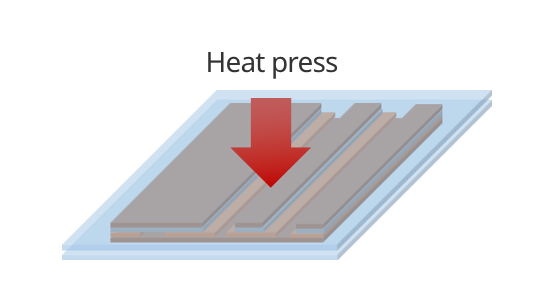

Features

-

Need to press at high temperatures and protect the object

Heat resistance

Usable at high temperatures (approx. 50~200°C)

-

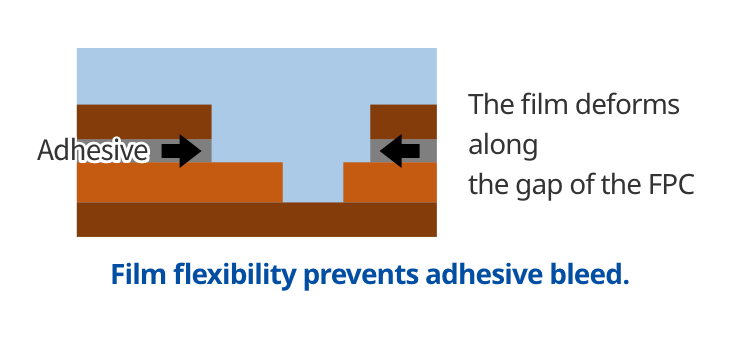

Need to flexibly deform to the uneven surfaces

High flexibility

Pliable deformation without wrinkling

-

Need to keep the object clean after heat press

Surface protection

/cleanlinessLow outgassing enables surface protection without contamination

Silicone and PFAS free -

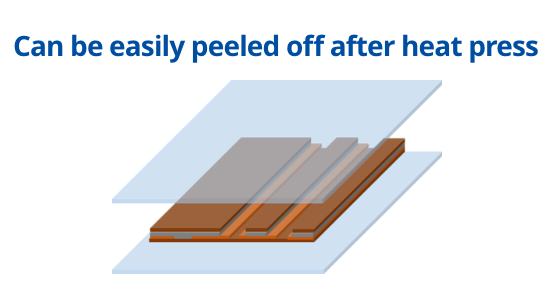

Need to peel off easily after heat press

High release performance

Can be easily peeled off after heat press

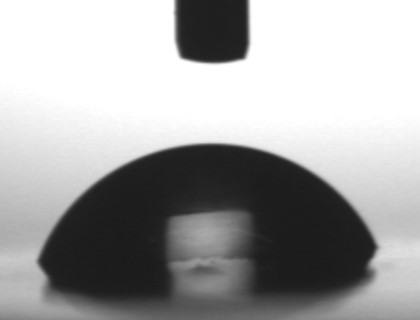

EvaluationFlexibility and heat resistance at high temperatures

Evaluation overview

- Evaluation method: Vacuum forming test

- Condition:200°C, 20 sec.

Results

SEKISUI product

Flexibly deform without wrinkling

Standard PET release film

Insufficient flexibility leads to wrinkling

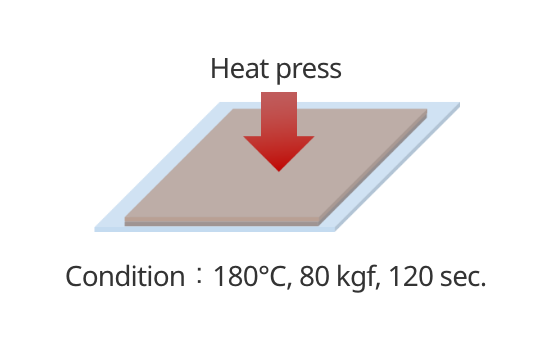

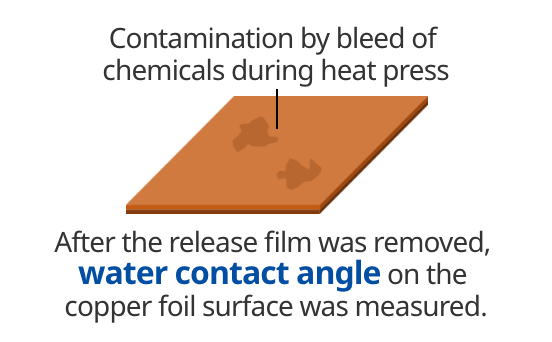

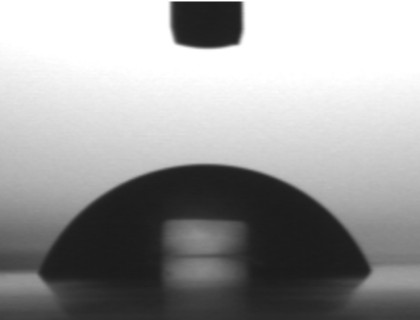

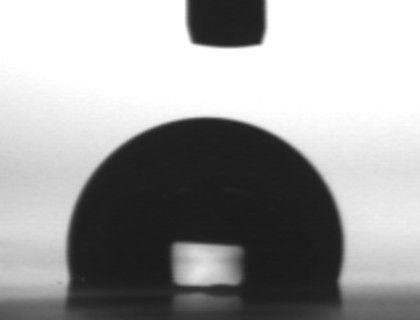

EvaluationCleanliness (low contamination)

Evaluation overview

- Evaluation method:Water contact angle measurement after heat press

Results

Our release film exhibits low outgassing properties and minimizes contamination after heat pressing.

Before heat press

SEKISUI product

Small change = Small amount of contamination

PMP* release film

Large change = Large amount of contamination

by bleed of water-repellent chemicals

- PMP: Polymethylpentene

Comparison with general-purpose films

Our release film can solve the trade-off in physical properties compared to various general-purpose films.

| Film Classification | ||||||

|---|---|---|---|---|---|---|

| SEKISUI product | Silicone-coated PET film |

PE film | PMP*1 film |

ETFE*2 film |

||

| General characteristics | Heat resistance | ○ | × | ○ | ○ | |

| Flexibility | × | ○ | × | ○ | ||

| Cleanliness (low outgas, low contamination) |

× | ○ | × | ○ | ||

| Release performance | ○ | ○ | ○ | ○ | ||

| PFAS-free | ○ | ○ | ○ | × | ||

| Silicone-free | × | ○ | ○ | ○ | ||

- PMP: Polymethylpentene

- ETFE: Ethylene/Tetrafluoroethylene Copolymer

Our release film offers versatile solutions across various industrial sectors with its heat resistance, flexibility, and low-contamination properties.

Applications

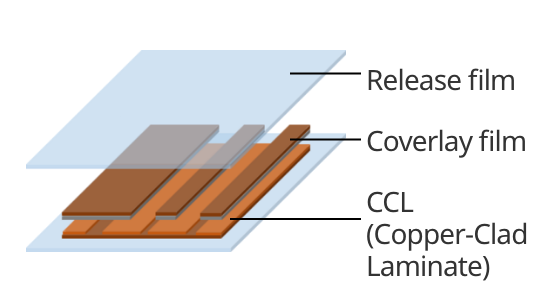

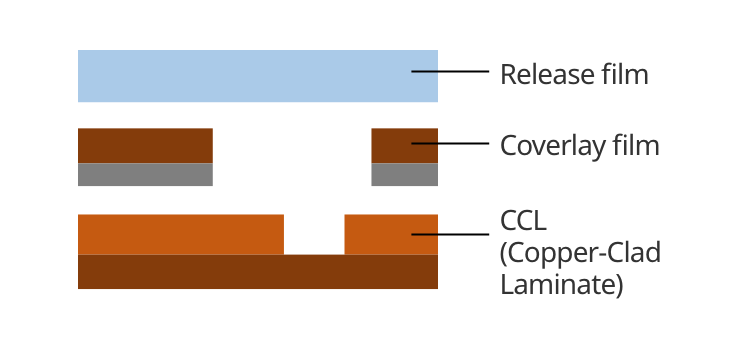

1Surface protection for the heat press process in circuit board manufacturing

- For manufacturing of flexible printed circuit boards (FPC)

- For manufacturing of rigid-flex PCB

Example: Surface protection in FPC manufacturing

- Heat press process of coverlay film and copper-clad laminate (CCL)

- Heat press process of reinforcement plates onto FPC etc.

Enlarged cross-sectional view

2Heat-resistant protection and buffering applications

- For manufacturing of semiconductor mold

- For manufacturing of carbon fiber reinforced plastics (CFRP)

- For buffering heat and pressure during ACF pressure bonding

- Other applications for protection and buffering during heat press process

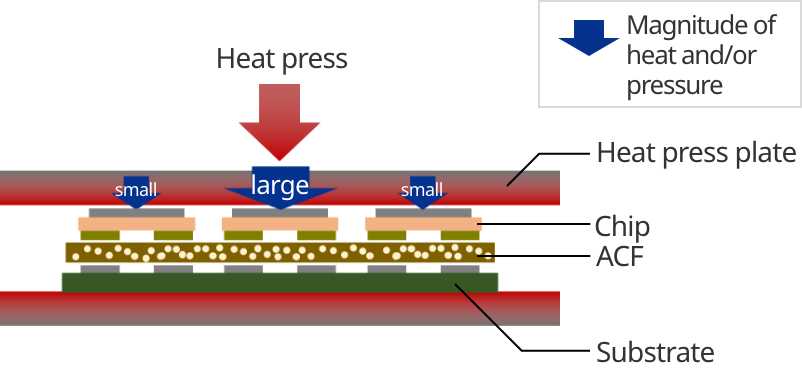

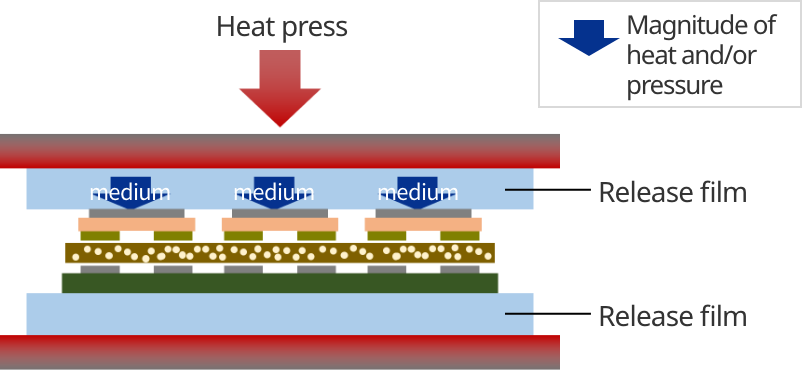

Example: Suppressing heat and/or pressure unevenness by buffering the chip during heat pressing

- Heat press process of ACF for manufacturing next-generation displays

Without release film

With release film

3Other applications

- For a heat-resistant flexible base material

Customization is available to meet your requirements.

Physical properties

Customization of physical properties is available to meet your specific requirements.

| E-type | A-type | J-type | |||

|---|---|---|---|---|---|

| Features | Highly flexible | Soft High elongation |

Hard Wrinkle-resistant |

||

| Average thickness | 100 µm | 190 µm | 110 µm | 120 µm | 120 µm |

| Melting point | 223℃ | 223℃ | 223℃ | 223℃ | 223℃ |

| Tensile yield strength at 23°C (MD direction) |

21 MPa | 20 MPa | 17 MPa | 30 MPa | 36 MPa |

| Tensile yield strength at 23°C (TD direction) |

18 MPa | 15 MPa | 15 MPa | 25 MPa | 28 MPa |

| Dimensional change ratio at 80°C (MD direction) |

-0.5% | -0.4% | -0.5% | -0.3% | -0.3% |

| Dimensional change ratio at 80°C (TD direction) |

-0.3% | -0.3% | -0.0% | -0.1% | -0.1% |

| Heat resistance | ★ | ★ | ★ | ★★ | ★★★ |

| Flexibility | ★★ | ★★ | ★ | ★ | ★ |

| Cleanliness | ★★ | ★★ | ★★ | ★★ | ★★ |

| Release performance | ★★ | ★★ | ★★ | ★★ | ★ |

| Roll size | Width 50~1400mm × Length ~1000m *Contact us for details on each product. | ||||

- The above physical property values are reference values based on typical products and are not guaranteed values.

Unsure which film is best for your application? Contact our experts today.

Our sales and technical support team are ready to assist you.

- Consult our experts to find the right release film for enhancing press temperature or controlling heat and pressure uniformity during your workplace's heat press processes.

- With extensive experience in the industrial film sector, our experts are ready to assist you to assist with any questions or provide advice on the best product for your specific application. Please contact us by clicking the button below.