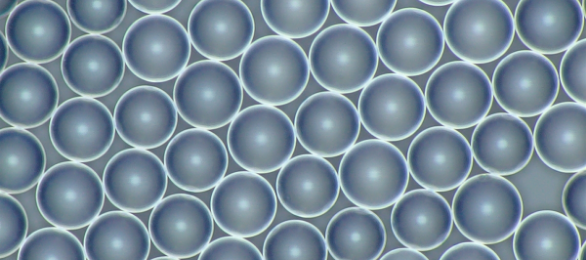

Plastic-based Micropearl™

- Top Page

- Microsphere (Micropearl™)

- Plastic-based Micropearl™

Plastic particles with uniform particle size distribution

They can be used in a variety of applications including gap formation in automobile parts and optical components.

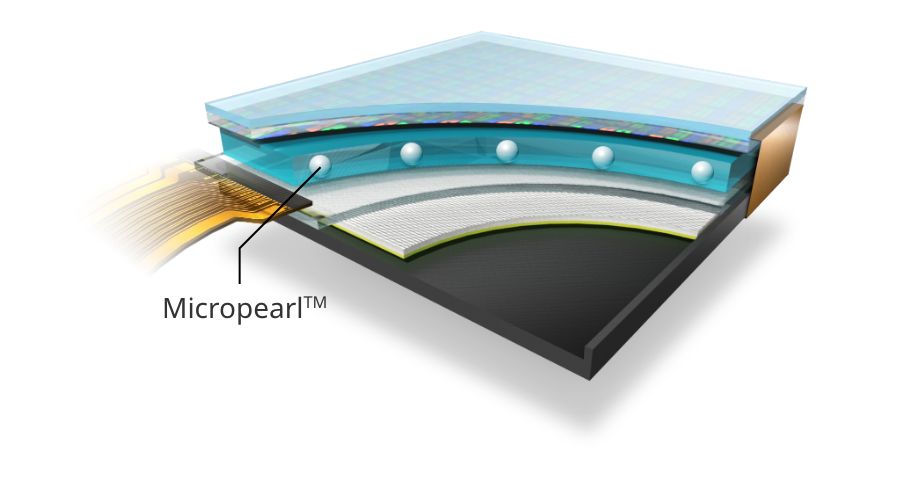

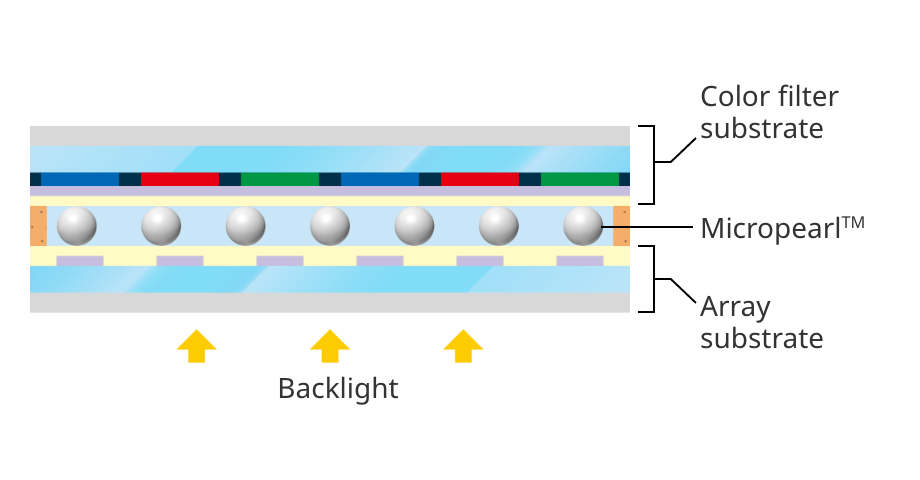

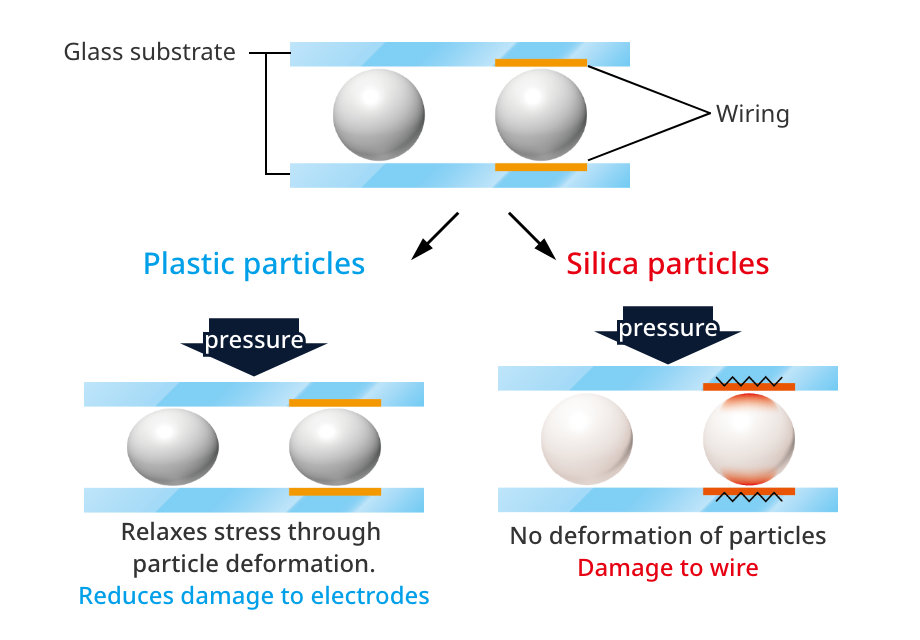

Thickness control of display panel

Challenge

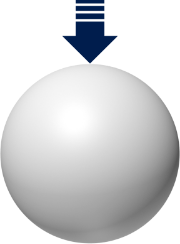

There are many liquid crystal displays (LCD) around us, and they support our convenient modern lives. In an LCD, clear and highly-responsive display is enabled by controlling the molecule orientation of the liquid crystal layer located between two glass substrates. For the liquid crystal layer, a precise gap control on the order of several μm is required, and therefore it is necessary to maintain a uniform height even when a small amount of pressure is applied to any portion within the surface.

SEKISUI's Solution

- Once Micropearl™ SP is dispersed in the liquid crystal layer, it functions as a high-accuracy spacer by taking advantage of its uniform particle size distribution.

- As Micropearl™ has a resin composition with flexibility, it reduces damage to the substrate and surrounding part/material even when a strong pressure is applied to it.

- Various particle sizes and hardness/resilience control allow us to offer products that suit customers’ demands.

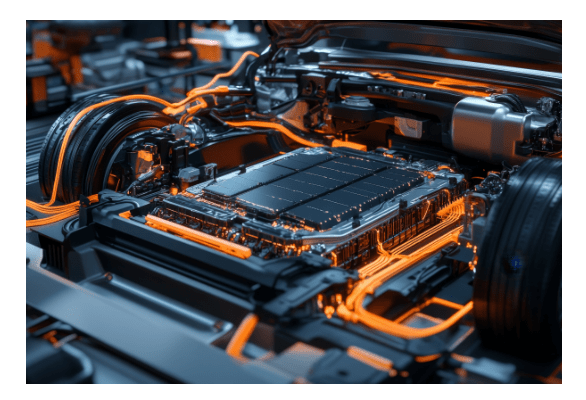

Relaxation of stress to solid electrolyte layer of all-solid-state battery

Challenge

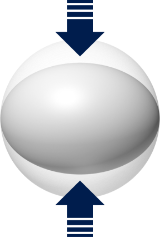

Toward realization of a carbon neutral society, the demands for storage battery in BEV (Battery Electric Vehicle), PHEV (Plug-in Hybrid Electric Vehicle), and others are increasing, and all-solid-state battery is anticipated to become a safe and high-performance next-generation battery.

The challenges in the development of all-solid-state battery include generation of internal stress in association with the expansion and contraction of anode/cathode and performance degradation due to defective contact between solid electrolytes associated with the internal stress.

SEKISUI's Solution

- Addition of Micropearl™ SP as stress relaxing agent is anticipated to reduce damage to part/material as it absorbs stress at the time of expansion and to maintain the contact between electrolytes at the time of contraction.

- Adding Micropearl™ to between collectors or between cells is anticipated to reduce damage to the surrounding part/material.

- Micropearl™ can also function as a spacer by taking advantage of its uniform particle size.

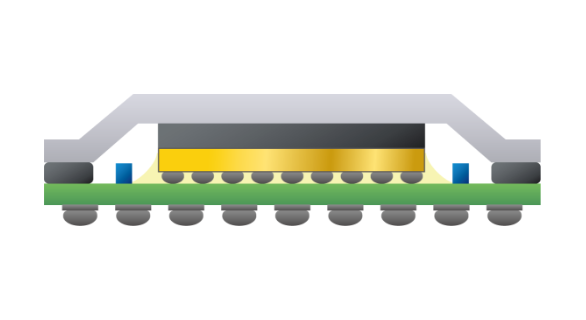

Formation of uniform gap between semiconductor element and substrate

Challenge

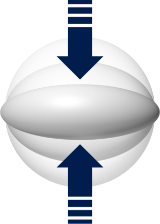

A power semiconductor is a device that has become necessary for equipping sensors/cameras on vehicle as the vehicle performance has been enhanced. In mounting of semiconductor chip on a substrate, advanced film thickness control of adhesion layer typified by solder paste and silver paste plays an important role.

However, it is difficult to manufacture a film at an arbitrary and uniform film thickness.

SEKISUI's Solution

- By kneading paste with Micropearl™ in advance, the adhesion layer exhibits a spacer function at the time of semiconductor mounting, and pressurized mounting achieves the same film thickness as the spacer size.

- Plastic-based Micropearl™, which exhibits better particle size uniformity, more flexibility, and lower specific gravity compared to glass beads, contributes to excellent handleability and improvement of product performance.

- It is also possible to plate the surface of Micropearl™ with metal of a high solderability.Please see here for details.

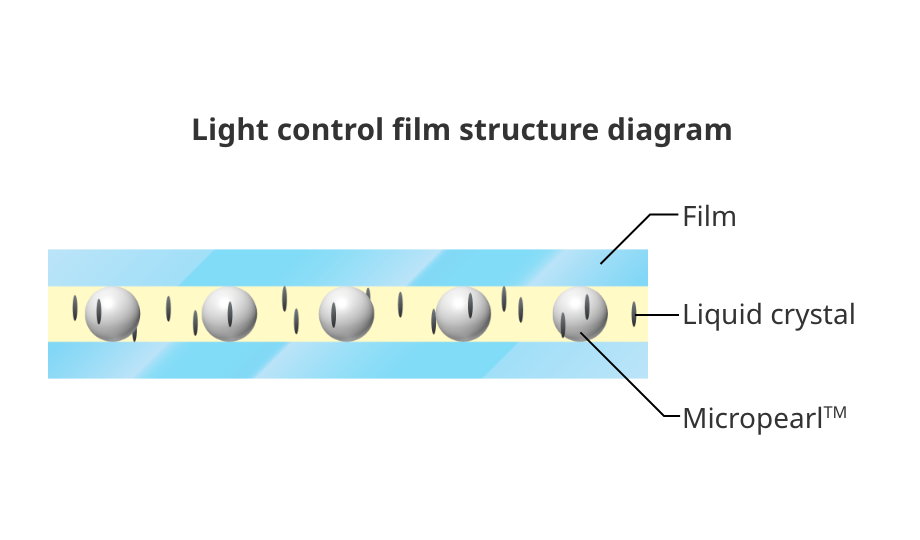

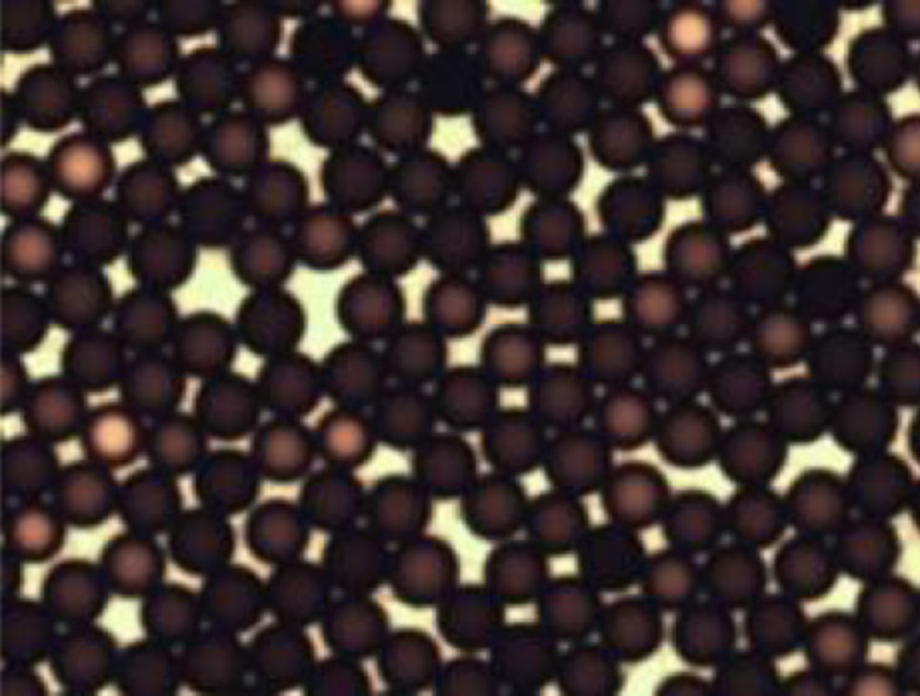

Glass light control

Challenge

In response to the needs for securing privacy and reducing in-vehicle temperature rise, and due to the convenience of its instant ON/OFF switching capability, light control film glass has been increasingly employed as vehicle exterior glass.

For light control film/glass, many properties including contrast, responsiveness, curved surface followability, and durability are required.

SEKISUI's Solution

- Due to its uniform particle size distribution and less large-size particles, Micropearl™ allows uniform gap control.

- With high flexibility and springiness, Micropearl™ prevents damage to substrate and particle movement.

- Excellent in voltage resistance, heat resistance, and chemical resistance, Micropearl™ contributes to retention of high reliability even in a high-temperature high-humidity environment.

Hardness/particle size lineup

- SP

- GS

- EX

overview

-

- SP

- GS

- Plastic particles with uniform particle size distribution

- Capable of uniform thickness control

- Voltage resistance, heat resistance, and chemical resistance

-

- EX

- Plastic particles with more uniform particle size distribution

→Capable of highly precise thickness control. - Excellent voltage resistance, heat resistance, and chemical resistance

- KB

- KY

overview

-

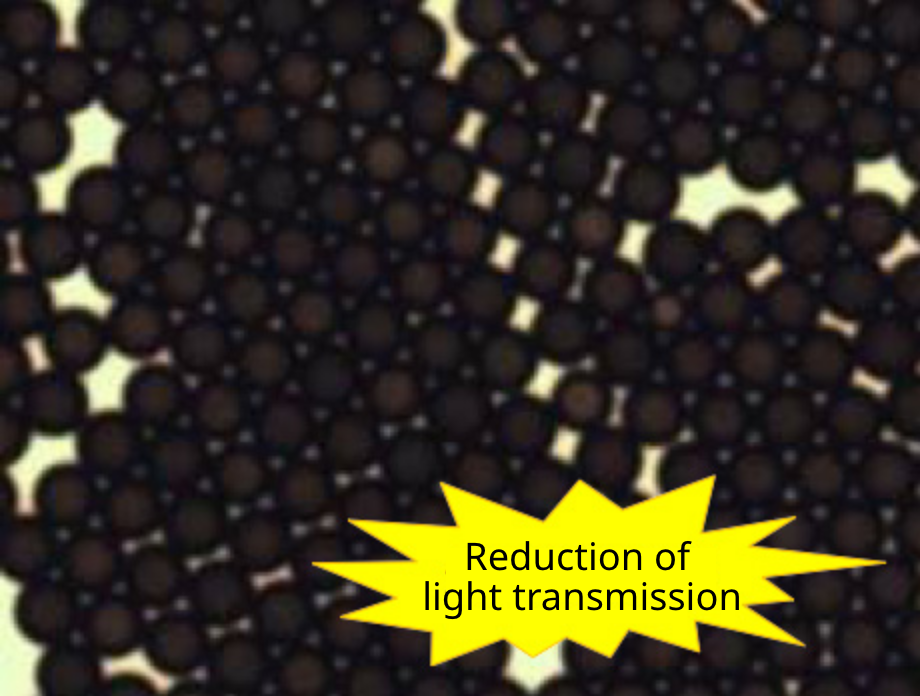

- KB

- Polymer particles dispersed with carbon black

- Excellent blackness, light shielding effect, resistance to exudation, heat resistance, and chemical resistance

→Usable in wide range of applications.

-

- KY

- Polymer particles dispersed with black “insulated” pigment

→Usable at parts subject to voltage when there is a risk of short-circuiting.

- EXH

overview

-

- Polymer particles with high hardness

→Excellent dimension stability against pressurization - Low specific gravity compared to glass beads

→ Prevention of sedimentation in resin

- Polymer particles with high hardness

- EZ

- SLC

overview

-

- EZ

- Polymer particles with flexibility

→Effective for reducing vibration noise and of damage to substrate - Low recovery rate

→Also optimum as gap material for soft base material such as film.

-

- SLC

- Silicone-based particles

- Capable of reducing vibration noise, reducing cure shrinkage, and soft base material thickness control.

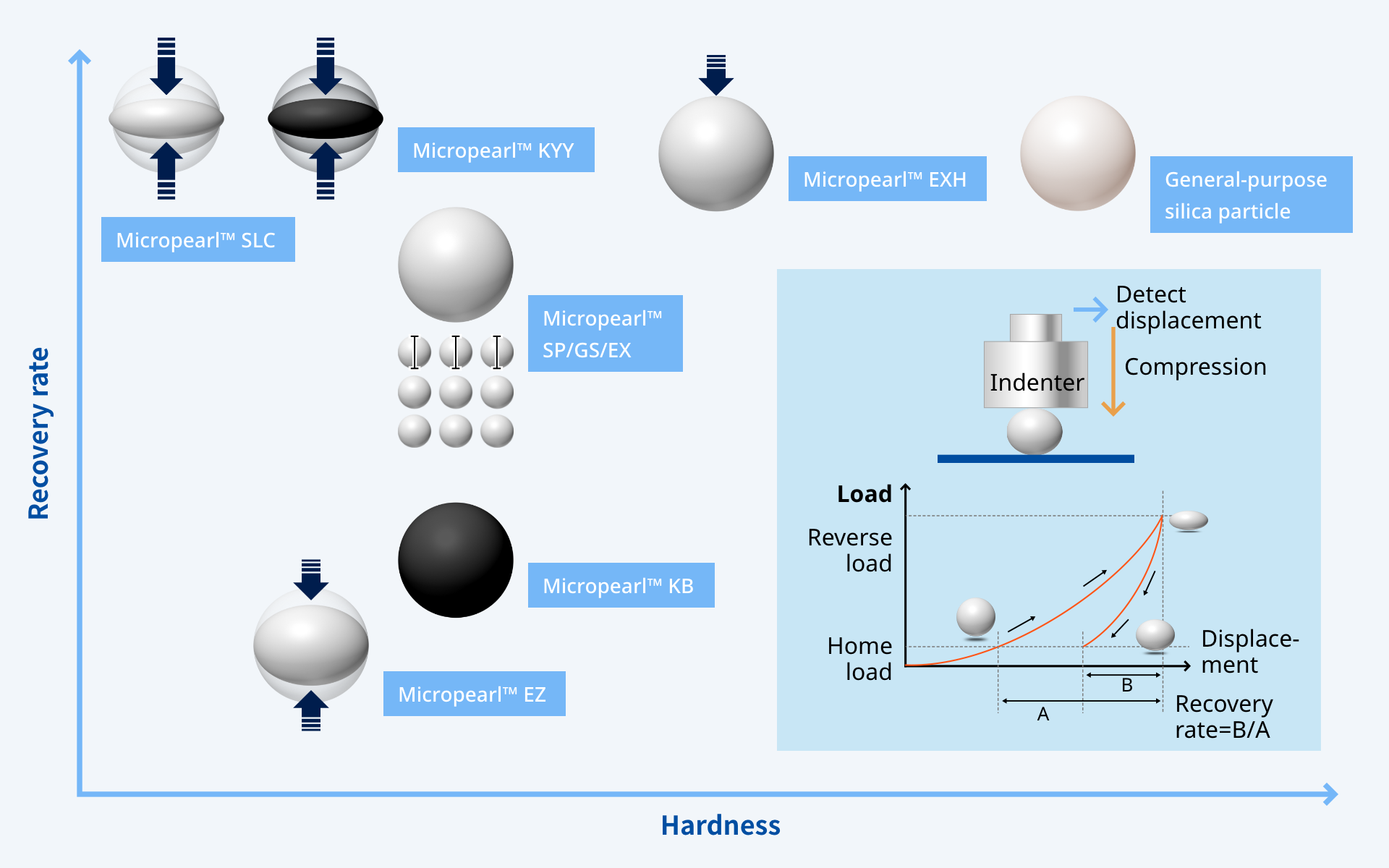

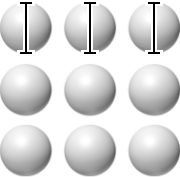

Comparison in hardness and particle size

We offer hard to soft products with particle sizes ranging from1.5 µm to 600 µm in accordance with applications.

Hardness

Particle size

Particle size

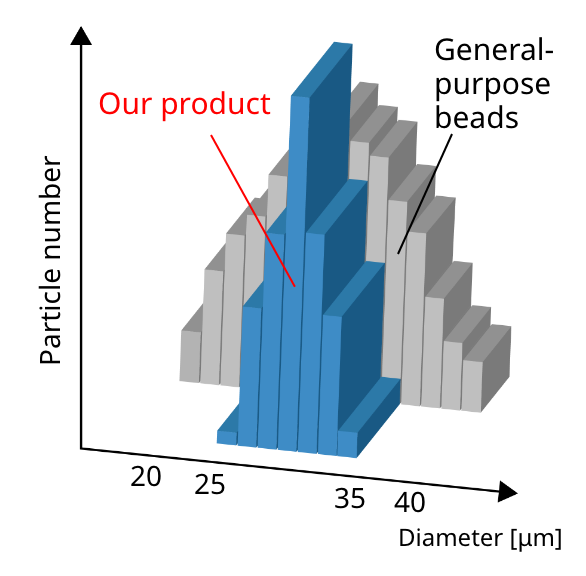

| Particle size | Cv | |

|---|---|---|

| Micropearl™ EX |

|

2〜3% |

| Micropearl™ SP |

|

5% |

| Micropearl™ GS |

|

7% |

Micropearl™ SP,GS,EX

Micropearl™ SP,GS,EX

- Small particle size

- Gap control

- Provision of embossing

- Simulated specimen

- Process saving

- Heat resistance

Plastic particles with uniform particle size distribution capable of uniform thickness control. Excellent in voltage resistance, heat resistance, and chemical resistance.

Advantages of using plastic particles

1Hardness control

Offering optimum hardness, not too hard nor too soft.

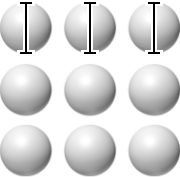

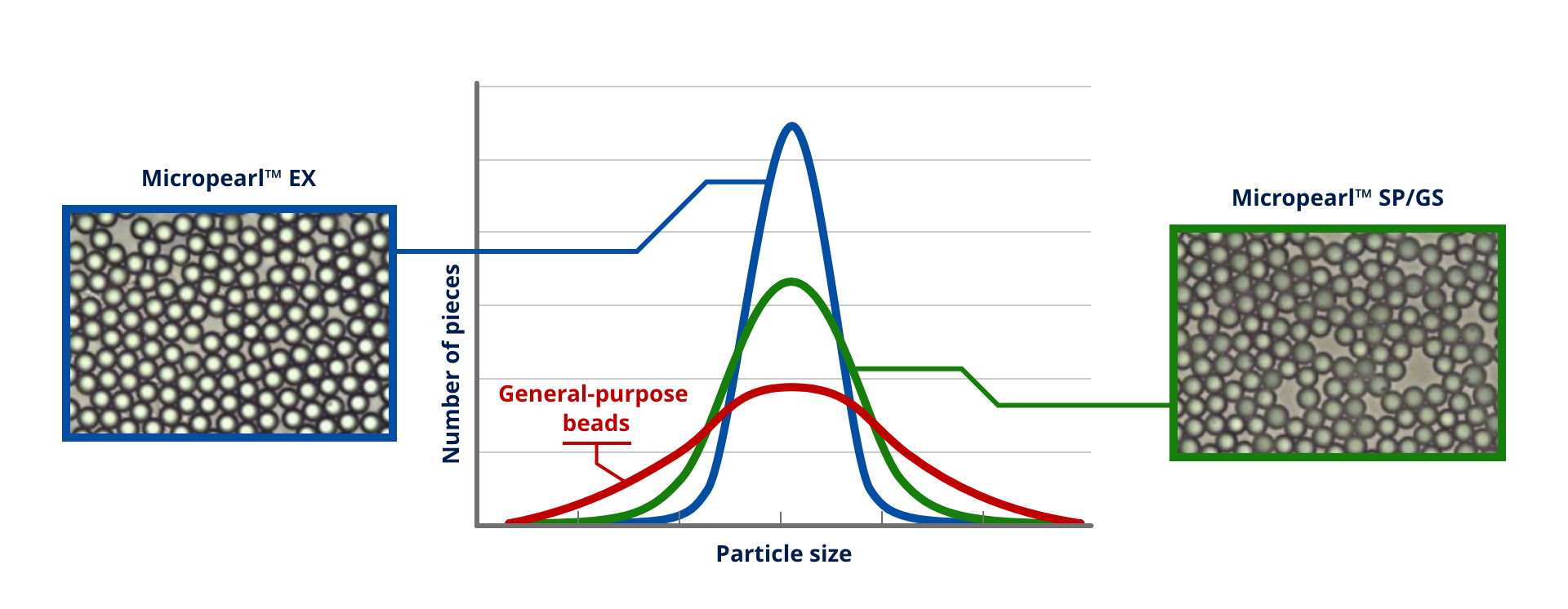

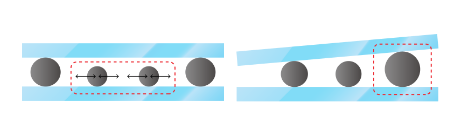

2Excellent particle size distribution

In pursuit of higher definition and higher precision at low Cv value.

| Micropearl™ EX | General purpose beads | |

|---|---|---|

| Cv | Low Cv (narrow particle size distribution) | High Cv (wide particle size distribution) |

| Image diagram |  |

|

| On vibration | Inhibit the movement of particles | Easy movement of particles |

| Number of particles | Higher number of particles engaged in gap control. Effective gap control with fewer particles. |

Fewer particles are engaged in gap control Higher number of particles required for gap control. |

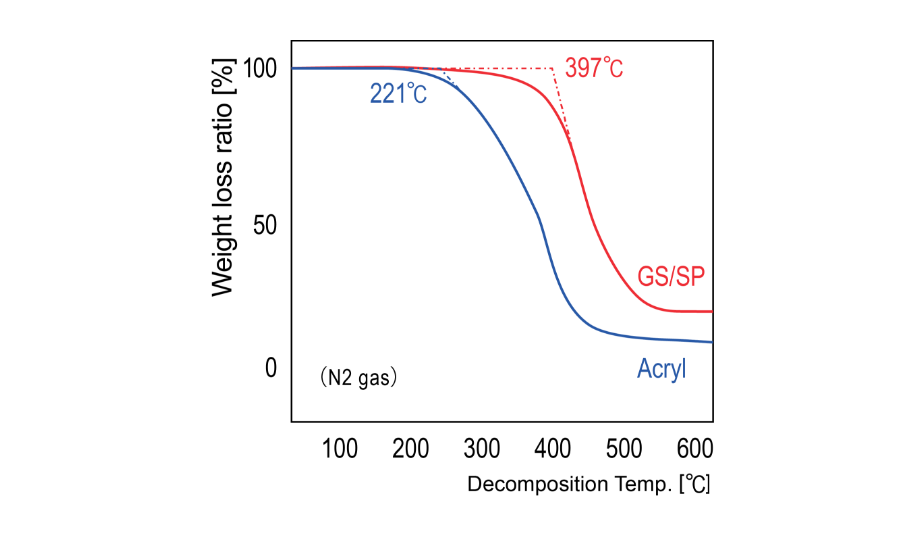

3Stability

Due to its excellent heat resistance compared to acryl particles, Micropearl™ is stable even in the temperature range of −40 to 200°C.

Applications

It is possible to provide a comb of particles and adhesives.

- LCD spacer (display/light control)

- Gap control for adhesive (Sensor/Enclosure/Other electric and optical components)

- Embossing molding material

- Simulated/inspection specimen

- Coloring agent containing particles

Micropearl™ KB,KY

Micropearl™ KB,KY

- Small to large particle sizes

- Gap control

- Provision of embossing

- Simulated specimen

- Process saving

- Light shielding effect

- Heat resistance

Polymer particles with black pigment dispersed, exhibiting excellent blackness, light shielding properties, and resistance to exudation and corrosion.

Excellent heat and chemical resistant products can be used in wider range of applications.

Advantages of using plastic particles containing black pigment

Applications

Please consider this model when Micropearl™ is required to have a light shielding effect.

- Display related applications

- Optical lens related products

- Simulated/inspection specimen

- Smart (light control) glass

Micropearl™ EXH

Micropearl™ EXH

- Hard

- Small to medium particle size

- Gap control

- Provision of embossing

- Process saving

- Heat resistance

Even though it is a polymer particle, it has excellent dimensional stability against pressurization due to its high hardness. Compared to inorganic particles, it also reduces damage to the substrate and prevents sedimentation in resin.

Advantages of using high-hardness plastic particles

Applications

- Substitution of Silica particles

- Can be added to adhesives for gap material.

- Gap material between glass substrates

Micropearl™ EZ,SLC

Micropearl™ EZ,SLC

- Soft

- Gap control

- Reduction of cure shrinkage

- Small to ultra large particle size

- Heat resistance

- Reduction of damage

- Hole forming

The model EZ, soft polymer particles, exhibits excellent vibration noise reduction and substrate damage reduction effects. Due to its low recovery rate, the model EZ is also optimum for gap control of soft base materials including film.

The model SLC, soft silicone-based particles, exhibits excellent vibration noise reduction and substrate damage reduction effects. This model exhibits heat resistance unique to silicone, and is chemically stable.

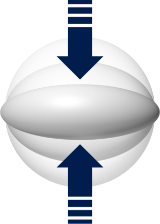

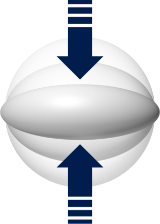

SLCAdvantage of using soft particles

As this model deforms in accordance with the pressure applied, damage caused at the time of mounting can be reduced.

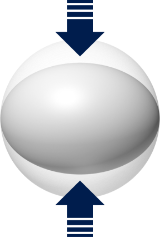

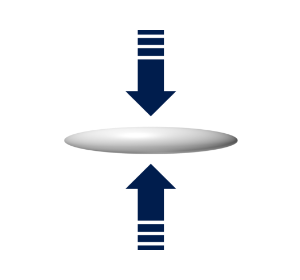

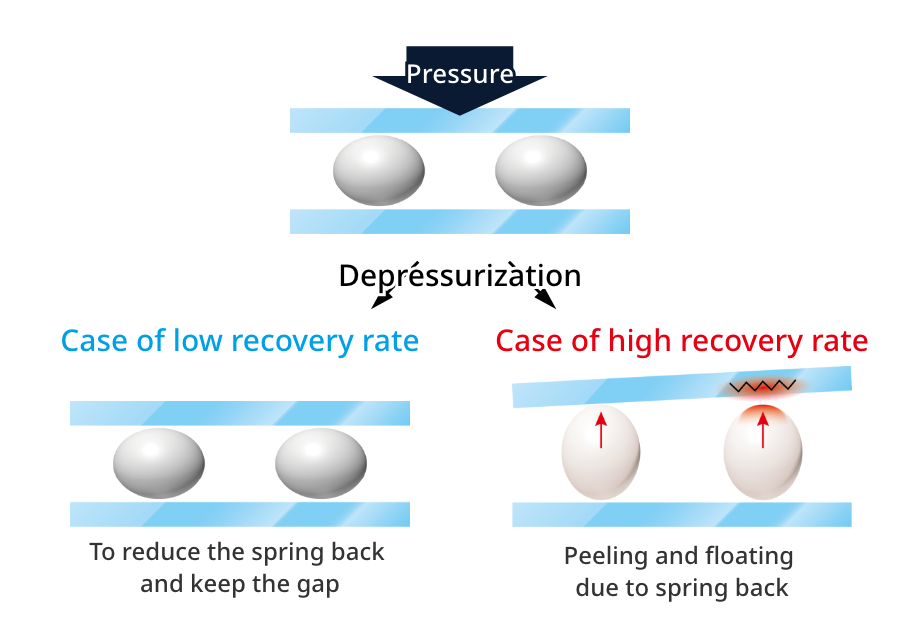

EZAdvantage of using soft particles with low recovery rate

- It is possible to minimize damage to the substrate, wiring, and others.

- It is possible to absorb vibration noise from the surrounding area.

- It is anticipated to reduce spring back, prevent adhesive layer peeling, and improve reliability.

EZApplications

- Adhesive for (pressure) sensor

- Conductive paste/die bonding agent

- Adhesive to be applied between films

SLCApplications

- Gap material for silicone adhesive

- Gap material for conductive paste/die bonding agent