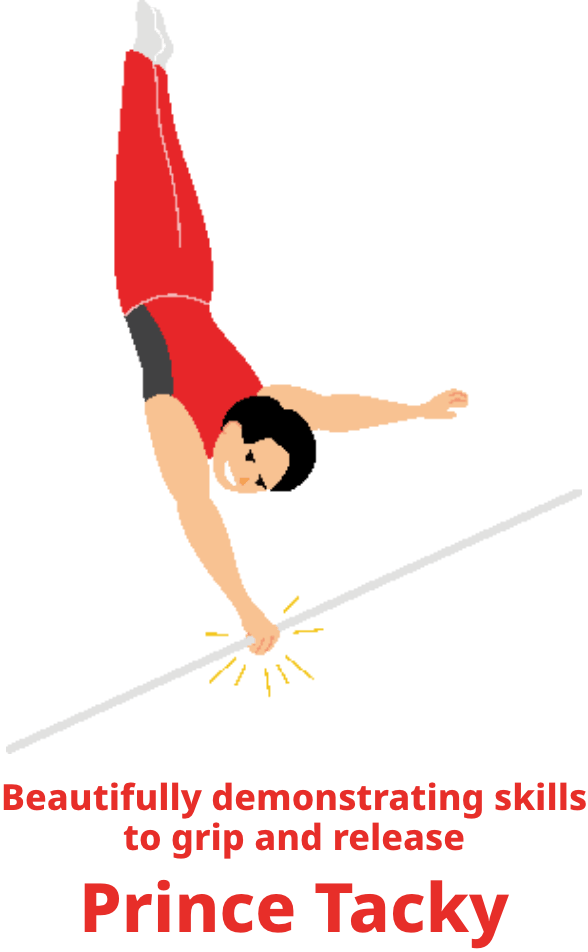

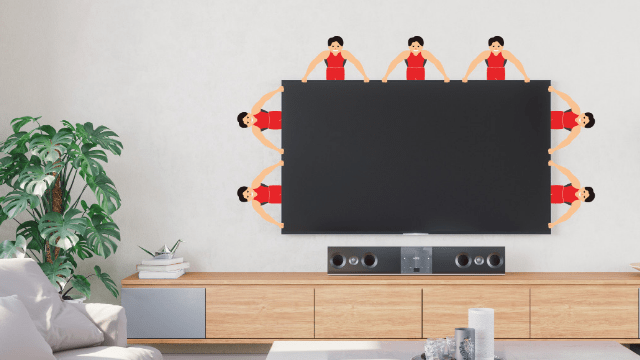

Beautifully demonstrating the skills

to grip and release

'Prince Tacky': Gymnasts

What is an acrylic?

Tacky and flexible plastics

Acrylics are plastics made from acrylic esters. Plastics are generally perceived as hard objects, but acrylics are very flexible and tacky to the touch.

Through combination with various acrylic esters, they are used for adhesive tapes and adhesives that can adhere to surfaces and be peeled off freely.

Familiar products in which acrylics are used

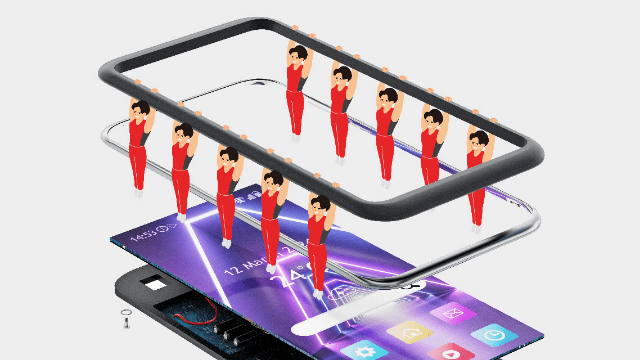

Adhesion of electronic parts in smartphones, etc.

Acrylics are often used as adhesive tapes and adhesives in familiar electronic devices. For example, they are used for many applications in smartphones, which are the most familiar electronic devices. The unique characteristics of acrylics are utilized to ensure adhesion in conformity to the shapes of electronic parts and long-term adhesion despite the hot environment inside.

Acrylics are similar to gymnasts.

Gymnasts demonstrate skills while gripping a horizontal bar or jump from a horizontal bar and grip it again. They flexibly and beautifully perform grips and transitions. Acrylics enable flexible adhesion, smooth peeling, and repeated adhesion.

12 main functions

Adhesiveness

Sticking the moment you apply

Gymnasts can start their performances the moment they grip a horizontal bar.

Acrylics also stick the moment they are applied to a material. This makes it possible to quickly apply.

Long-term reliability

Continuing to stick over the long term without peeling

Gymnasts can continue to grip a horizontal bar and spin around the bar. Similarly, acrylics remain firmly stuck to a material after use over the long term.

Peelability

Can be removed from a material with a clean peel

Gymnasts perform beautiful transitions. Similarly, acrylics can be easily removed from a material with a clean peel.

After a gymnast releases the grip, the horizontal bar remains smooth. The material remains clean without leaving traces of adhesion.

Reusability

Reappliable after peeling due to retained tackiness

After a jump for a transition, gymnasts can immediately grip a horizontal bar again. Similarly, acrylics also remain tacky after being peeled from a material.

Acrylics remain tacky after sticking and peeling cycles, making it possible to reapply repeatedly

Heat resistance

No deterioration in a high-temperature environment

Gymnasts have trained in hot gymnasiums despite the summer heat.

Similarly, acrylics do not easily deteriorate when subjected to a high temperature and can remain firmly stuck. Thus, they are often used to mount automotive and other parts that are subjected to high temperature.

Weatherability

Remaining stuck even outdoors due to high weatherability

Gymnasts have undergone severe training to perform despite wind and rain.

Acrylics are resistant to ultraviolet rays, high temperature and humidity, and weather, and remain firmly stuck. Thus, they are suitable for outdoor use.

Chemical resistance

No deterioration when exposed to chemicals

Gymnasts maintain their grip on a horizontal bar even when they are exposed to slippery chemicals.

Acrylics do not deteriorate easily when exposed to various chemicals (solvents and plasticizers) and remain firmly stuck.

Impact absorbing performance

Absorbing and dispersing impact with high flexibility

Gymnasts use their knees to flexibly mitigate the impact of landing. Similarly, acrylics can disperse the energy of impact because they are flexible plastics.

Even if an electronic device is dropped, acrylics mitigate the impact and protect parts from damage.

Strain relaxation performance

Relaxing strains between materials

For gymnasts, the flexibility of their bodies is extremely important.

Acrylics take full advantage of their flexibility to disperse strains applied during use. For example, acrylics eliminate the difference in the expansion rate when different materials are stuck together and prevent distortion of products.

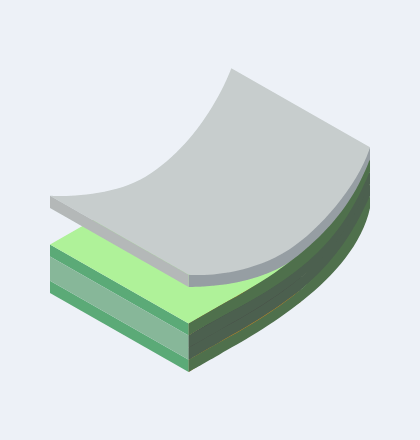

Adaptability to uneven/

curved surfaces

Capable of adapting to any surface to fill gaps

Because acrylics are flexible plastics, they can adapt to uneven or curved surfaces of materials and fill the gaps. They also adhere to gaps between materials that are stuck together and demonstrate high sealing performance.

Transparency

Transparent and color-stable

Some gymnasts have become transparent and invisible in pursuit of beauty of their performances.

Acrylics are suitable for adhesion of glass and transparent plastics because they are transparent and color-stable.

Workability

Can be processed into any shape

Gymnasts can be formed into any shape because their bodies are soft.

Acrylics can be processed into any shape before they are stuck to materials. Thus, they are highly convenient and used widely in the industry, including LCD TV sets, mobile phones, and vehicles.

Applications of acrylics

Mounting parts in mobile devices to prevent failure

Acrylics are used to mount parts in mobile devices, such as smartphones. For example, acrylics stick the main unit of a device, a panel, and small parts together.

The high impact absorbing performance prevents damage when a device is dropped, and the adaptability to uneven surfaces demonstrates waterproof and dustproof performance. Excellent workability makes acrylics suitable for mounting of parts of various shapes.

Functions

Impact absorbing performance

Adaptability to uneven surfaces

Workability

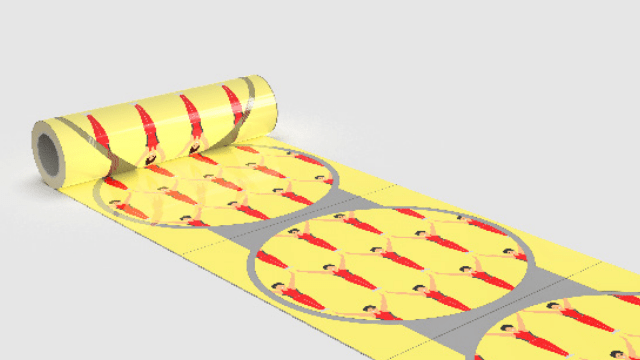

Keeping display panels mounted over the long term

Acrylics are used to mount display panels. Even heavy panels can be securely mounted with high reliability.

Due to excellent flexibility, acrylics suppress display uniformity issues, which arise in line with the growing panel size. When recycling displays, tapes can be peeled easily to disassemble displays and recycle materials.

Functions

Long-term reliability

Strain relaxation performance

Peelability

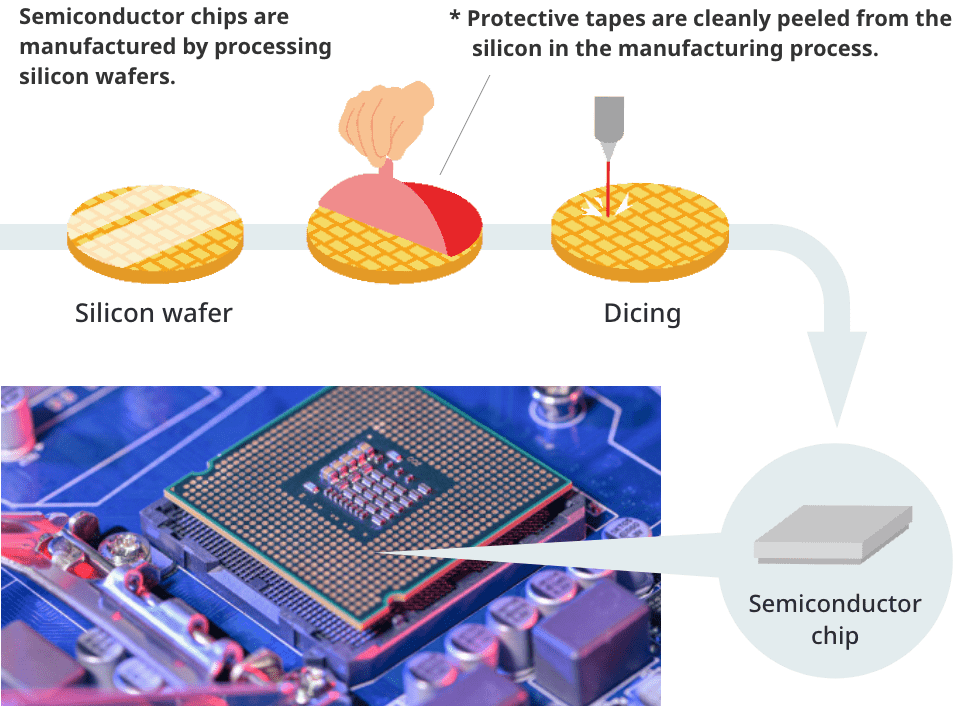

Protecting the surface when manufacturing semiconductors

Acrylics are used for protective tapes when manufacturing semiconductors, which are indispensable for computers. Such tapes protect semiconductors without peeling even during the severe semiconductor manufacturing process due to high heat resistance and chemical resistance.

After semiconductors are completed, such tapes can be removed without damaging semiconductors while keeping the surface clean due to high peelability.

Functions

Peelability

Heat resistance

Chemical resistance

Introduction of products

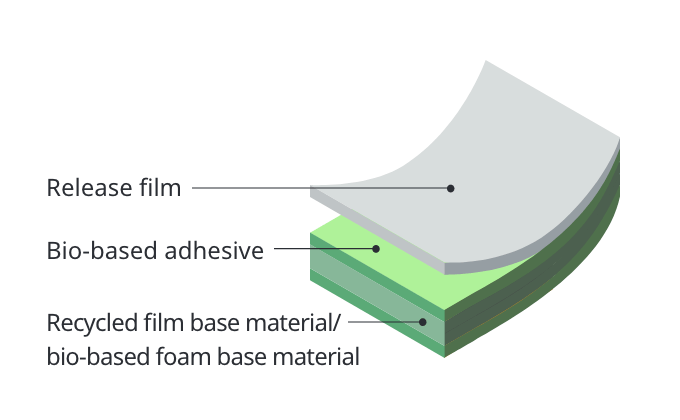

Bio-based tapes

These eco-friendly adhesive tapes help reduce CO2 emissions by using raw materials derived from plants and recycling.

New Products Born from Core Technology

There has been growing demand for sustainable and eco-friendly products. Adhesive tapes are also required to maintain adhesiveness and functionality equivalent to those of conventional products by using biomass or recycled materials.

The bio-based tapes that we developed realize adhesiveness equivalent to or higher than that of petroleum-based products by using adhesives whose raw materials derived from plants account for 73%, which is among the highest in the industry.

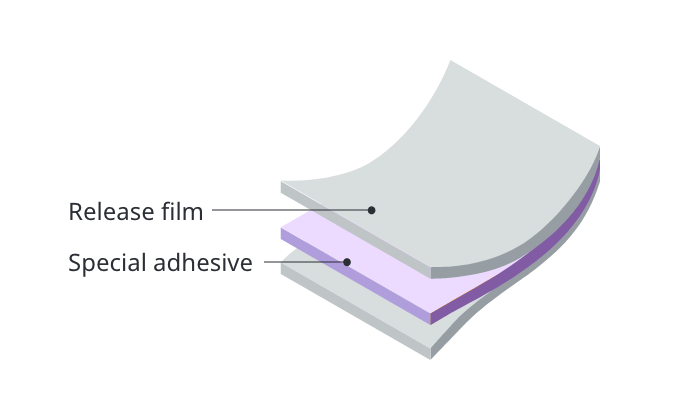

Double-coated adhesive tapes for fluoroplastics (newly developed product)

This double-faced tape can also be used for fluoroplastics, whose adhesion is difficult, by using a proprietary compound developed through analysis of secretions of blue mussels.

New Products Born from Core Technology

Fluoroplastics are used in various industries due to excellent heat resistance, chemical resistance, electrical properties, nonadhesiveness, and lubrication properties. Meanwhile, it was extremely difficult to bond with other materials due to chemical inactivity.

The double-coated adhesive tapes for fluoroplastics, which we are currently developing, achieve good adhesion to fluoroplastics, which was considered impossible before, by using special adhesives.

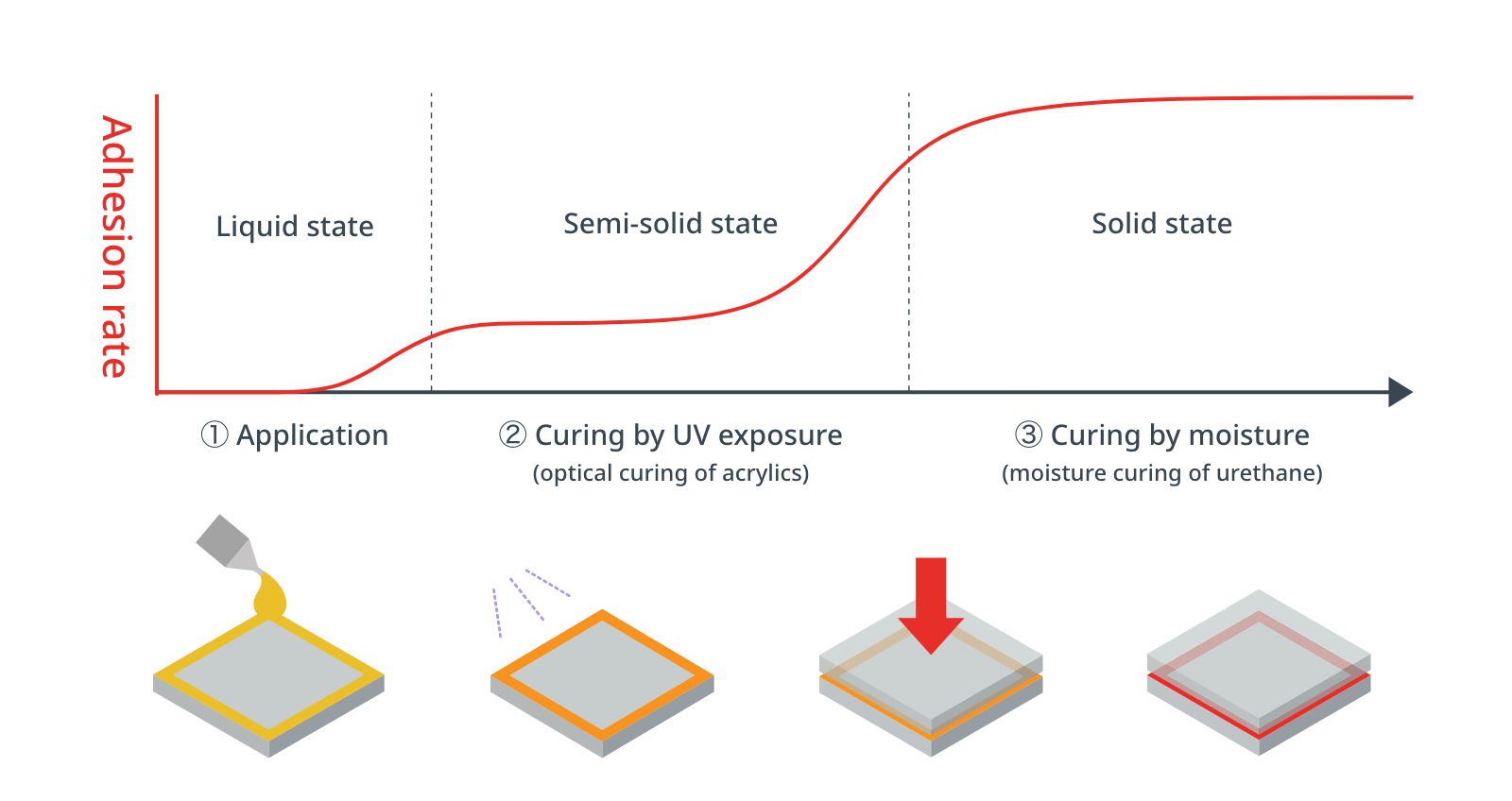

Photolec™ B

This is a two-step curing adhesives (optical curing of acrylics and moisture curing of urethane). It ensures initial adhesive strength and reliability by combining the strengths of double-faced tapes and adhesives.

New Products Born from Core Technology

When applied Photolec™ B is exposed to ultraviolet rays, it becomes semi-solid. Materials can be stuck together while Photolec™ B is in the semi-solid state, enabling adhesion like tapes without dripping. Subsequently, airborne moisture causes the curing process to progress further, ultimately resulting in highly reliable adhesion.