Sekisui's ADVANCELL EM is a functional microsphere that foams when mixed with resin and heated.

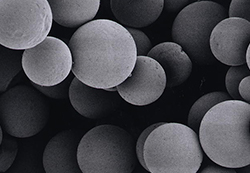

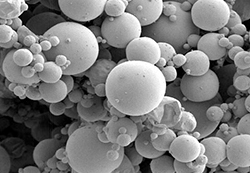

ADVANCELL EM is comprised of thermo-expandable microspheres (tiny plastic spheres) containing a low-boiling-point liquid hydrocarbon inside a thermoplastic polymer shell. When heated, the shells soften and, at the same time, the hydrocarbon contained inside suddenly expands, forming micro-balloons. Mixing ADVANCELL EM with a resin (base material) adds a variety of desirable characteristics and features to the material, such as reduced weight and enhanced flexibility.

Expansion ratio of ADVANCELL EM

Expands 3 to 4 times in diameter and 50 to 80 times in volume.

| Before expansion | After expansion | |

|---|---|---|

| Average particle diameter |

15~40μm | 40~150μm |

| Density | 1.00~1.20g/㎝³ | 0.01~0.03g/㎝³ |

"Expansion" solves many issues in a variety of fields.

■ Building materials

Wallpaper, flooring material, synthetic wood, paint, putty/sealing material, lightweight clay

■ Automotive parts

Interior material(door trim, ceiling material),exterior material, paint(automotive sealing material),paintUBC , Adhesive

■ Daily commodities

Adhesive, Shoe soles, synthetic leather, cork

Adhesive, Shoe soles, synthetic leather, cork

■ Foaming resins

EVA, PE, PVC, PP, ABS, EPDM, TPE .etc

■ Applicable processes

Coating, injection molding, extrusion molding, blow molding, press molding

The high-quality expansion characteristic is one of the great features of ADVANCELL EM.

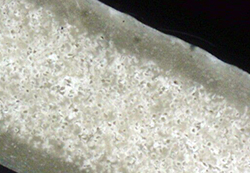

●Independent micro-balloons result in a high-quality finish not offered by other chemical foaming agents.

Since ADVANCELL EM is comprised of shells (polymer cells), the micro-balloons feature an independent, closed-cell structure. ADVANCELL EM offers the following advantages over a chemical foaming agent made mainly of ADCA (azodicarbonamide).

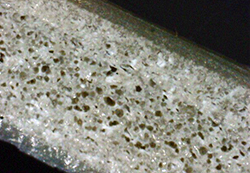

■Fine, uniform micro-balloons achieve a smooth surface.

■The sharp particle size distribution achieved by Sekisui's proprietary technology allows the micro-balloon size to be controlled.

■Micro-balloons can be formed even in low-viscosity compositions.

- ADVANCELL EM

-

Surface

Smooth surface

-

Cross section

Uniform, tiny independent bubbles

- Chemical foaming agent

-

Surface

Generation of silver

-

Cross section

Non-uniform, large continuous bubbles

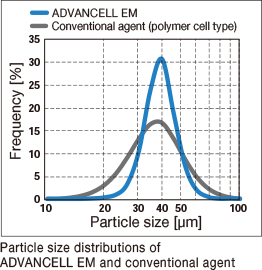

●Expansion of ADVANCELL EM is more uniform than that of a conventional agent of the same type because of the sharp particle size distribution.

Thanks to Sekisui's proprietary particle dispersion technology (patented), ADVANCELL EM offers more uniform and sharper particle size distribution as compared to those of other expansion type foaming agents of the same type, thus producing a smooth and refined finish. Since ADVANCELL EM maintains a constant amount of heat necessary for expansion and stabilizes the expansion start temperature, it enables easier control of the processing temperature.

- ADVANCELL EM

- Uniform micro-balloons result in:

- ○Formation of uniform cells

- ○Smooth and refined finish

- ○Reduction of expansion loss so that only a small amount of ADVANCELL EM needs to be added

- ○Easy to control the processing temperature

- Conventional (polymer cell type)

- Non-uniform expansion results in:

- ×Formation of irregular cells

- ×Rough finish

- ×Generation of expansion loss due to unexpanded particles

- ×Difficulty to control the processing temperature

ADVANCELL EM Specifications

Particle grade

| Grade | EML101 | EMH204 | EHM302 |

|---|---|---|---|

| Average particle size | 12~18μm | 36~44μm | 15~25μm |

| Expansion start temperature (Ts) |

115~130℃ | 110~130℃ | 130~140℃ |

| Maximum expansion temperature (Tmax) |

155~175℃ | 160~180℃ | 160~170℃ |

| True specific gravity after expansion |

0.017±0.005 | 0.013±0.005 | 0.016±0.005 |

| Grade | EHM303 | EM306 | EM403 |

|---|---|---|---|

| Average particle size | 24~34μm | 20~30μm | 25~35μm |

| Expansion start temperature (Ts) | 120~130℃ | 135~145℃ | 150~170℃ |

| Maximum expansion temperature (Tmax) | 160~170℃ | 170~180℃ | 200~220℃ |

| True specific gravity after expansion | 0.016±0.005 | 0.016±0.005 | 0.016±0.005 |

| Grade | EM406 | EM501 | EM504 |

|---|---|---|---|

| Average particle size | 24~34μm | 21~31μm | 15~23μm |

| Expansion start temperature (Ts) | 140~150℃ | 160~180℃ | 160~180℃ |

| Maximum expansion temperature (Tmax) | 180~190℃ | 210~230℃ | 190~210℃ |

| True specific gravity after expansion | 0.016±0.005 | 0.016±0.005 | 0.020±0.005 |

Master batch grade (pellets)

| Grade | P501E1 | P504E1 |

|---|---|---|

| Average particle size | 21~31μm | 15~23μm |

| Expansion start temperature (Ts) | 160~180℃ | 160~180℃ |

| Maximum expansion temperature (Tmax) | 210~230℃ | 190~210℃ |

| Base material | PE | PE |

According to the application, a particle grade or master batch grade can be selected.he expansion start temperature and cell size can be optimized by selecting an appropriate grade. Please feel free to contact our company for details.