S-LEC B / K(KS)

Polyvinyl Acetal Resin S-LEC B / K (KS)

- Overview

- Chemical Structure

- Features

- Applications

- How to Use

- Control Properties

- Specification

- Downloads

Overview

Polyvinyl acetal resin (S-LEC B/K) with excellent physical properties :

Toughness, Adhesiveness and Dispersibility

- S-LEC is composed of three units:

acetal group, acetyl group and hydroxyl group. - In addition to general polyvinyl butyral resin (PVB), various resins with

different structure and ratio of the acetal group is available. - By adjusting the ratio of each group and degree of polymerization,

it is possible to control the material properties for various applications. - Can be used in a wide range of applications such as binders, dispersants

and adhesives

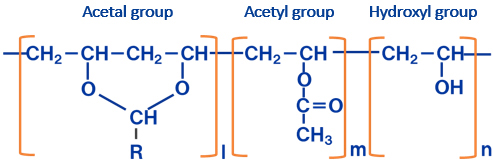

Chemical Structure

PVB resin is a polymer composed of three units: acetal group, acetyl group, and hydroxyl group.

The resin name differs depending on the structure of the “R” in the acetal group.

R : -C3H7⇒ S-LEC B

( Polyvinyl Butyral / PVB )

R : -CH3⇒ S-LEC K

( Polyvinyl Acetacetal )

*The above two are collectively called “polyvinyl acetal resin”.

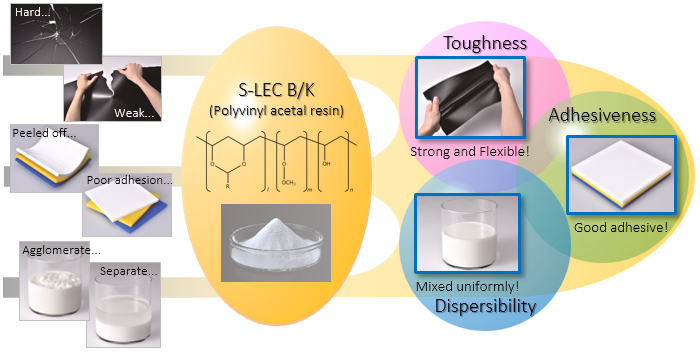

Features of Polyvinyl Acetal Resin

Notable features of polyvinyl acetal resins are toughness, adhesiveness, and dispersibility.

In a variety applications, these features provide ideal product properties and good handling during

the manufacturing process.

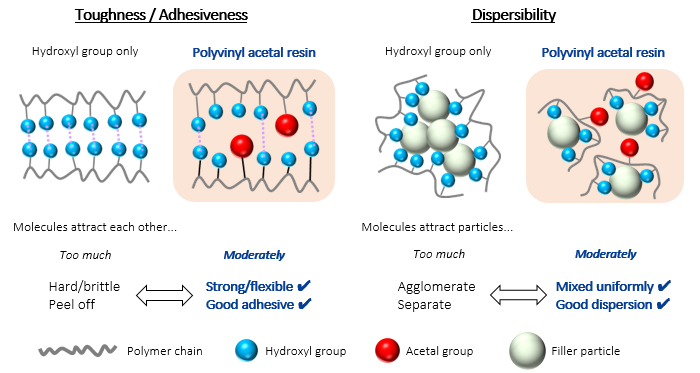

■Mechanisms for functional expressions

Polyvinyl acetal resin has the above features because it contains a good balance of high polar hydroxyl groups and low polar acetal groups.

Applications

Polyvinyl acetal resins are used in a wide range of applications, including binders for MLCC and other ceramics, binders for conductive pastes, dispersants for pigments and carbon materials, modifiers for epoxy and phenolic resins, inkjet receptive layers, and adhesives and so on.

How to Use S-LEC and Its Effects

By dissolving in a solvent suitable for each application and mixing with other materials, the adhesive properties and dispersibility characteristic of S-LEC can be demonstrated in products and their manufacturing processes.

Control of Material Properties

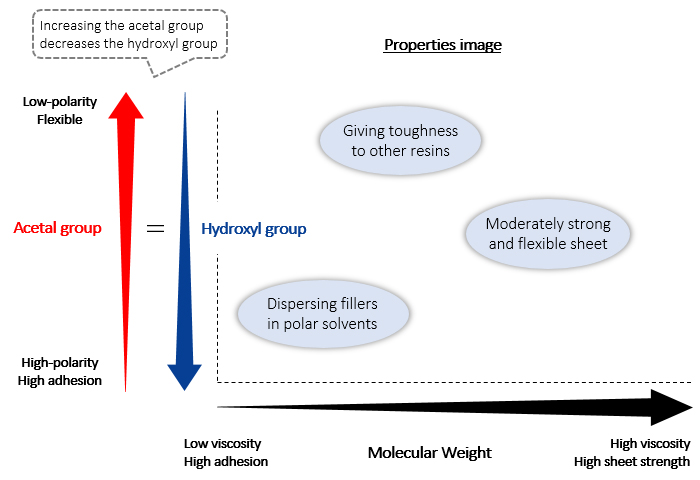

The chemical and physical properties of polyvinyl acetal resin can be controlled by adjusting the molecular weight and the ratio of the three units. This allows us to propose suitable grades with properties that meet your needs.

* In addition, Tg and solubility, etc. can be adjusted by changing the amount of acetyl groups.

* We also have a lineup of water-based PVB with a high hydroxyl ratio.

Product grades

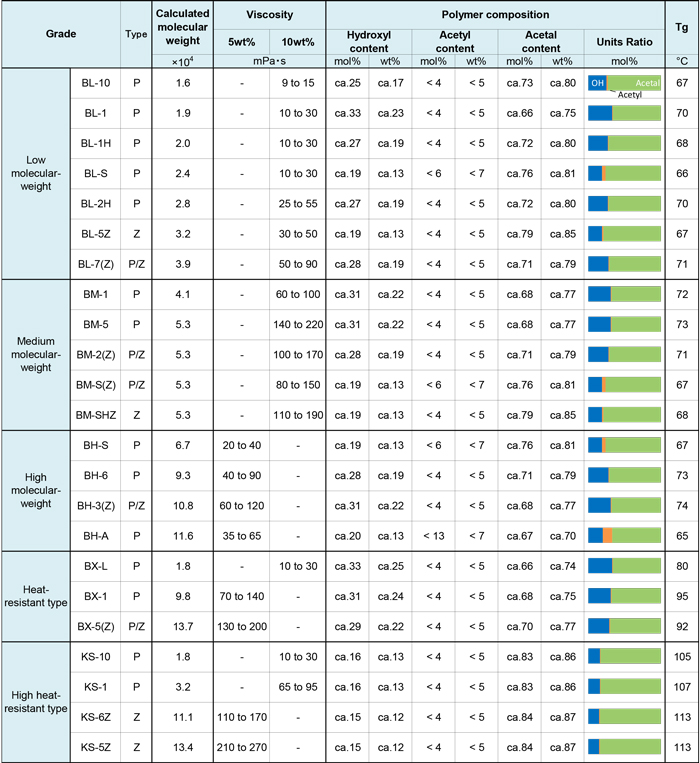

■Grades and properties

Viscosity : Ethanol / Toluene = 1/1 solution ( rotational viscometer / 20ºC)

*The above values are reference values, not guaranteed values.

Hydroxyl group

Acetyl group

Acetal group

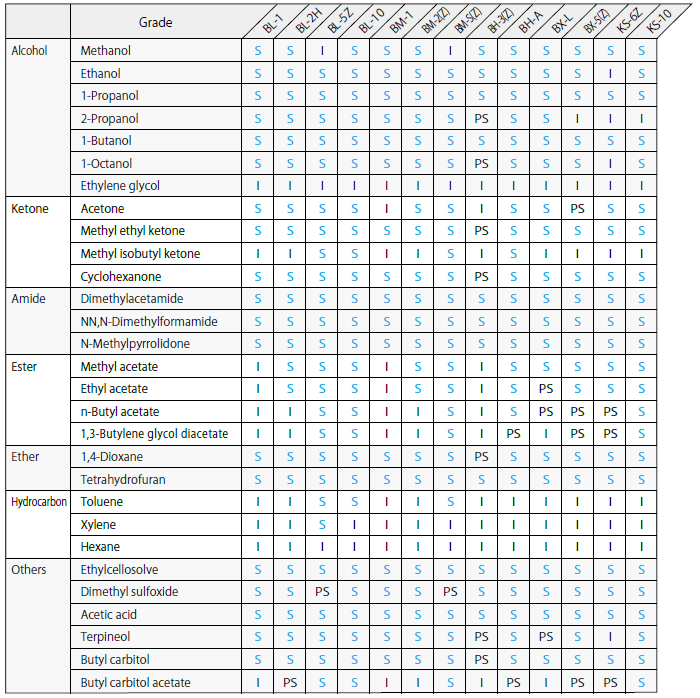

■Solubility

* Resin concentration : 5 wt%

* Solubility: S (Soluble), PS (Partially Soluble), I (Insoluble)

Downloads

| Contents | File name | File size | |

|---|---|---|---|

| S-LEC B/K Product Catalog | S-LEC(EN) certification, technical data, etc. | 2.95 MB |

↓ Download |

| S-LEC K KW/KX Product Catalog | S-S-LEC_KW-KX(EN) certification, technical data, etc. | 0.77 MB |

↓ Download |